Trimble, a precision ag technology provider, is teaming up with ag equipment manufacturer Horsch to introduce a new, self-propelled crop protection sprayer.

The sprayer relies on sensor data and GNSS (global navigation satellite system) to navigate around fields. While it does require an operator to be on board, the vehicle has automated steering and speed control based on a preplanned trajectory and is also programmed to stay within a prescribed area (i.e. a field boundary) through geofence technology.

The solution will initially be available on Horsch self-propelled sprayers in the PT and VL series, which are available in various configurations with a patented suspension concept and boom widths of up to 36 metres. Existing machines released in 2018 and later can be retrofitted with the automation module from Trimble.

Jeremy Leach, director of autonomy for Trimble’s agriculture group, says there’s no firm date for the release of the self-propelled sprayers in Canada but it will be sometime later this year.

The new sprayer is capable of full-field execution, which is a step up from guidance systems that are more limited in what they can do, adds Leach.

“The limitations are that you have to take control and turn corners. You can’t take your attention off of it because (the vehicle) is basically going from one spot to the next rather than doing the complete job,” he says. “That, for us, was an obvious area where we can actually improve the efficiency of the operator.”

Full-field execution means the Trimble sprayer knows where to start, where to end and which paths to follow as it executes a spraying plan for a field. It can be programmed to avoid or take the same path around static obstacles in a field as well.

“It also allows the operator to utilize the active tank level to trigger material refills,” says Meiko Martin, product manager with Trimble Autonomy. “The machine will automatically switch off the application control at the end of a row, travel to a defined logistic point and stop. After the refill, the operator will engage the system and it will travel back to the resume point, start the application control automatically and resume the spray job.”

Read Also

New Holland concept tractor a nod to its Fiat brand heritage

New Holland’s exhibit at Agritechnica included this “concept” farm tractor with Fiat stylings that pay homage to the company’s Italian heritage.

Trimble maintains its latest innovation is an example of how autonomous machinery is quickly moving from a futuristic dream to a realistic option for modern farmers.

“Technology has been accelerating over the last decades, and it’s not going to get any slower,” says Martin, adding Trimble is certainly no stranger to the autonomy space. Another recent example is Robo, a cab-less, two-tracked tractor being developed by Horsch that is equipped with Trimble guidance and path planning technology.

Trimble helped pioneer GNSS technology 40 years ago, Leach notes. “(GNSS) is a key aspect of autonomy. Knowing where you are in the world is fundamental to making an autonomy solution work,” he says. “About 20 years ago, Trimble started releasing guidance for steering controls. Again, this is the key component to autonomy solutions.

“We have a legacy in this space of delivering technology components piece by piece,” Leach adds. “It’s not necessarily obvious to people who think about autonomy as a complete package solution that does everything for you, but autonomy is made up of lots of small components or building blocks that when they work together, they give you that complete solution.”

Different levels of autonomy

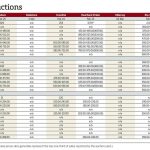

A classification system has been developed for autonomous vehicles (see Table 1 below).

Trimble’s self-propelled sprayer falls in the Level 2 category of advanced driving assistance, but the company has no intention of stopping there.

“The future is going to be an evolution rather than a revolution,” says Leach. “What we’re doing is we’re adding more and more technology into that Level 2 space, kind of as a series of building blocks that allow us to then step up to Level 3.”

Leach likens the process to filling a bucket with water. “You get enough of the technology into the bucket and, all of a sudden, we’ve now crossed that threshold where we can minimize the risk, we can do things safely and we can actually provide value to the farmer at a higher level. But we’ve got to keep filling that bucket first,” he says.

Level 2 solutions like the self-propelled sprayer are constrained by the fact that someone always needs to be in the vehicle to ensure it doesn’t accidently hit something or run someone over, Leach says. The next evolution of Trimble’s autonomous strategy will see unmanned vehicles running on their own, although operators will need to be somewhere close by to monitor vehicle operation and to take control remotely, if necessary.

“One of the reasons why we’re looking at Level 2, before Level 3, before Level 4, is we actually want the farmer to be sitting on the vehicle as it does all the work to build confidence that they’re happy with the job it does before they take a step back and say, ‘I’m going to stand at the gate or the fence and I’m going to look and observe,’” says Leach.

“We move up through higher levels of autonomy by adding things like the perception stack. The perception stack is made up of a camera or radar or lidar or quite often all three, as well as a lot of sophisticated algorithms to determine what it sees in front of it, for example, a person, a shrub, tumbleweed, or whatever it may be. You can actually move into that functionally safe environment,” he adds.

“A lot of the technology to do that is already out there today. It’s being used today. And so, a lot of it comes down to how confident are you in that technology, how robust is it and what are the edge cases? Because no one wants to be run over by a tractor.”

Safety first

Leach stresses safety will always be a primary consideration as Trimble rachets up its autonomous solutions.

“There will always be risk — the same as driving a car or operating heavy machinery. There is always risk but we need to minimize it as much as we can,” he says. “It’s all about making sure we get the edge cases under control and the risk is really, really minimal.”

Leach sees a time when “the robot or the tractor is out there doing work in the middle of the night and the farmer is fast asleep because at this point it’s functionally safe, it won’t hit anything, and the farmer trusts that it’s going to do the job right. That’s the long-term vision.”

Leach says Trimble will likely have some Level 3 autonomous ag solutions ready for the marketplace within “a couple of years or more,” with Level 4 solutions arriving several years after that.

Leach acknowledges some farmers may be distrustful of autonomous technology, which is an important reason why Trimble doesn’t want to rush the release of its autonomous ag products.

“I know there are definitely farmers that are going to be suspicious of this,” he says. Feedback Leach has received from farmers has ranged from, “Why can’t I have one today?” to “Hell, no. That’s never coming on my land.”

“That doesn’t surprise me at all,” says Leach. “The early adopters are the people we will probably work with first because they’re desperate for whatever assistance they can get. Winning the trust and maintaining the trust and not abusing the trust of people who are a little skeptical is something we will work on.

“I think there is definitely a kind of uncertainty that we’re going to walk through for the next 10 years as these solutions come to market, as they take responsibility for more and more activities and they become trusted by the farmer.”

The benefit of small, incremental steps is they allow autonomy developers to validate things as they go along, he adds.

“The horizon is beckoning, but it’s not all going to get launched this year or next year. It’s going to be a constant release of products over time,” he says.

“(We) are going to build up to a complete Level 4 solution where a farmer will be confident to say, ‘Hey, I’ve seen that machine do all of the activities I want it to do, and it does them to a standard I consider acceptable. And now I’m willing to let that machine do that work for me because I’m going to focus my time, my attention, my energy and my intellect on something of more value.’”