To say there has been ramped-up interest in planters from Prairie farmers in recent years might be an understatement. That’s because manufacturers have been blending the precision placement ability planters can achieve with features aimed at canola growers. This year Horsch introduced growers to its newest models, the Maestro SW 4715 and 4815, at the Ag in Motion farm show near Langham, Saskatchewan.

These two new planters from Horsch are designed to offer growers a single machine that can seed both small-seeded crops like canola and still plant corn and soybeans, which means farmers experimenting with corn and beans in relatively small acres could now better justify the expense of purchasing a planter.

The Maestro SW 4715 is a 47-row planter with 15- and 30-inch row spacing capabilities mounted on a 60-foot toolbar. The Maestro SW 4815 is a 48-row planter with 15- and 30-inch row spacing capabilities also on a 60-foot toolbar. It’s designed especially for planting between existing rows in no-till applications.

Standing beside an SW 48-15 model, Jake Rissmann, director of service at Horsch, talked with Grainews about its features.

“We call it a split-row planter,” he said. “It’s new for full production this year. You can run canola at 15-inch spacings or lift every other row unit and seed corn on 30-inch spacings. All you have to do to lift the rows, is there’s a lever on the front of the machine, you pull the lever up, and when the fan is running it uses hydraulic oil to raise the rows.

The Maestro on display at AIM was setup with a 700-gallon front tank for liquid starter fertilizer, with two side-mounted saddle tanks that combine to add another 500-gallon liquid fertilizer capacity to the machine. It’s one of the configurations available. The planters come standard with an 83-bushel seed capacity and 770-gallon liquid fertilizer capacity. Owners can configure the main liquid tank for seed and add saddle tanks to give the unit 250 bushels of seed capacity and still carry 1,000 gallons of liquid fertilizer for extended run times, says the company.

“The two rear tanks on that machine are both 83-bushel product or seed tanks,” explains Rissmann. “We do have some dry machines, but capacity is not likely what people are going to be looking for in this part of the world, so most guys are choosing the liquid machines.”

Rissmann adds that one of the biggest advantages of using a planter for canola is that it can reduce per-acre seed requirements. And it can still produce yields comparable to those fields seeded at higher rates with a drill.

“Right now we’re seeing canola results where customers are using half the seed they normally use with an air seeder to get the same yield results at the end of the year,” he says. “For this part of the world, where a lot of guys are just getting into corn and soybeans, they need a machine to do those crops, but maybe they don’t put in enough acres to justify the machine. And that’s where the canola comes in.”

Read Also

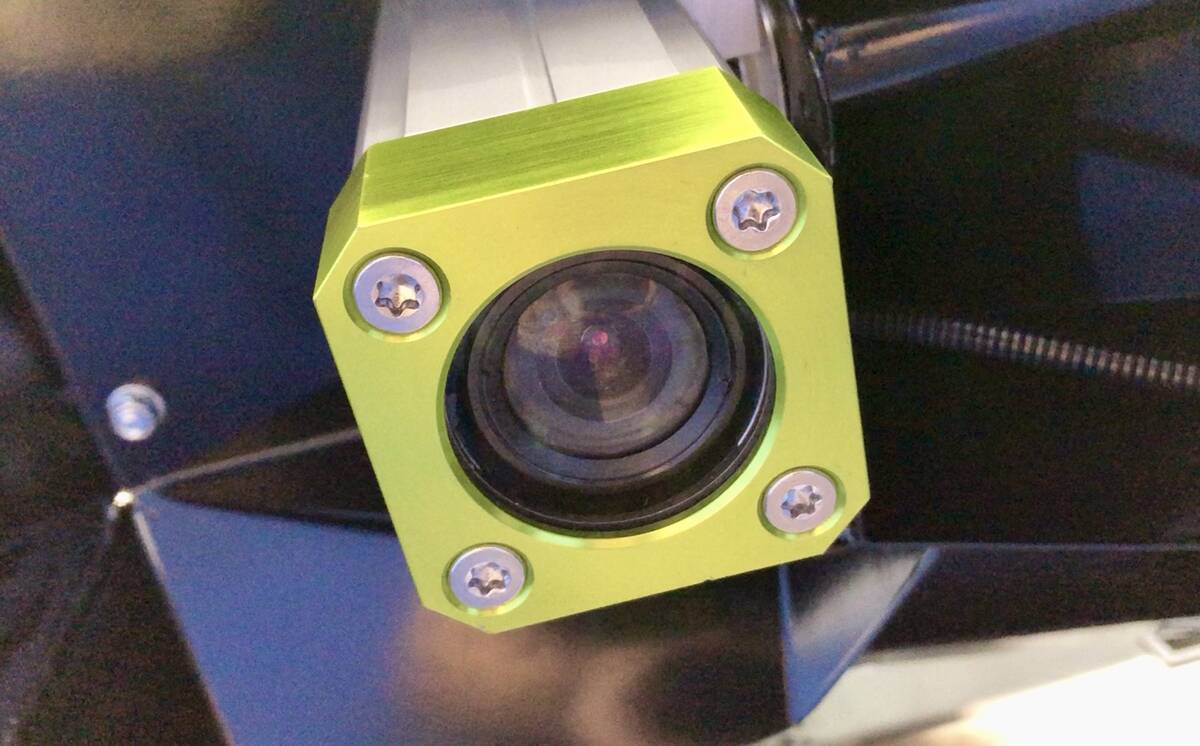

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

And although a 60-foot working width is pretty respectable in itself, Rissmann adds that the Maestro planters can compete with drills that offer still wider widths, because of the speed they operate at.

“This 48-row unit has a working width of about 60 feet, and guys typically plant in that seven m.p.h. range,” he explains. “Typically with a hoe drill, you might be travelling four or five miles per hour. You may have a wider width than 60 feet, which this machine is, but you’ll be running at seven m.p.h. or so, depending on ground conditions.”

Both the Maestro SW 4715 and 4815 use electric motor-driven metering units with individual row shutoff and curve compensation, hydraulic down pressure on the row units, a planter weight transfer system, and precision monitoring via ISO Virtual Terminals or Horsch monitors. The company claims they also offer the largest seed and liquid fertilizer capacities in the industry.

Other standard features on the Maestro SW planters include four pivot points on the toolbar, which allows them to closely following ground contours. Large-diameter tires improve floatation and create a lighter footprint, while helping to eliminate pinch rows.