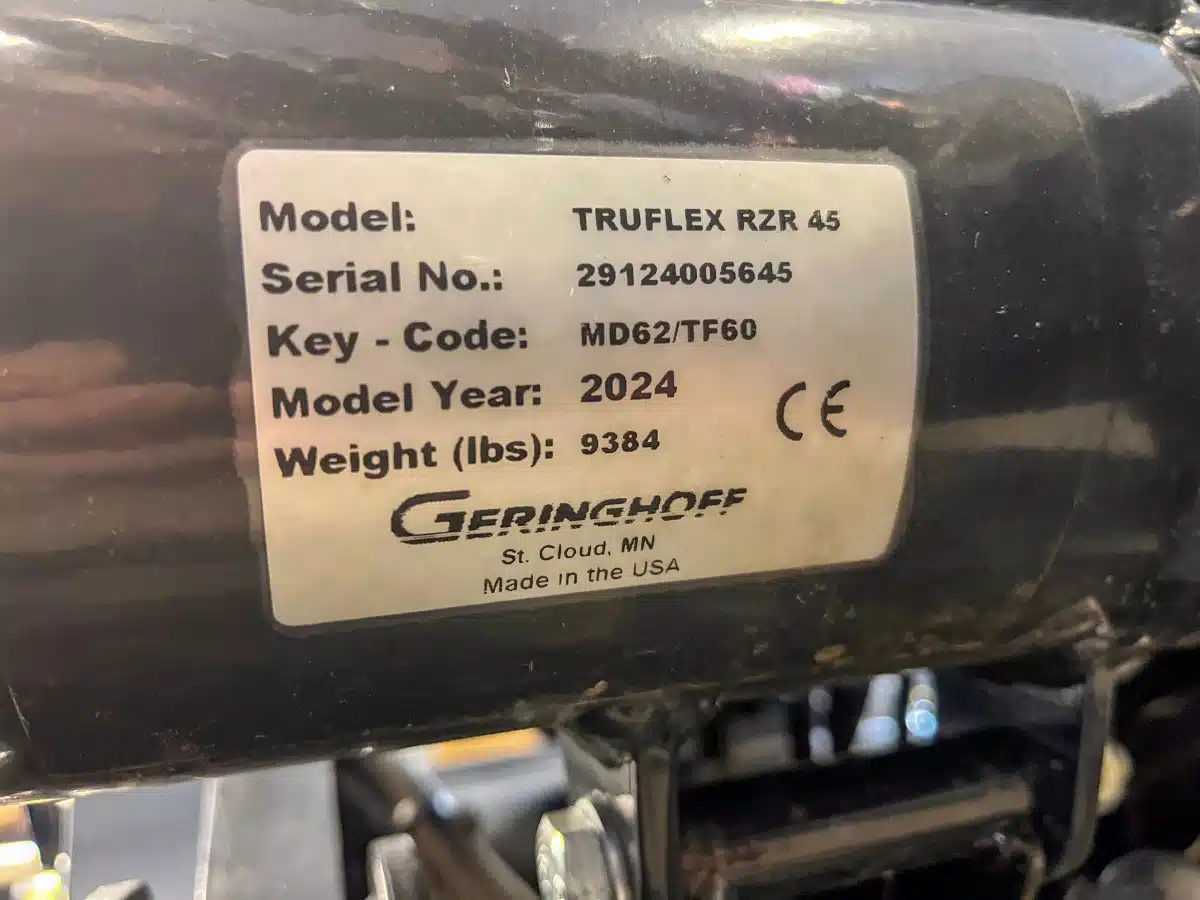

One of the European implement brands that have set up shop in North America in recent decades is Geringhoff, a combine header manufacturer based in Germany — and it’s offering Canadian producers a draper model its western Canadian territory manager, Lucas Haas, calls a premium design.

Geringhoff’s TruFlex Razor Draper header offers some unique features that help reduce kernel loss and improve material flow, including the Integrated Air System (IAS).

In that system, a fan mounted on the rear of the header forces air up from the cutter bar toward the rear of the belts to prevent kernel loss at the front of the header over the cutter bar.

Read Also

John Deere introduces updated tech for its combine line

The 2027 model year will see the debut of several new features for John Deere’s line of combines, particularly the X9.

“Nobody else has that,” Haas says. “It’s something unique. We started here in Western Canada in 2020 and tested it and improved it. We now have about 140 headers out (in Canada) and 80 per cent of them have the air system on it.

“We started testing at Olds College. In Europe we’ve tested with different varieties of canola. Here when we tested it (against) a header without (IAS); it’s over a bushel, about one and a half (in loss savings). When you have a head without the air system, (loss) went to two, to two and half bushels sometimes. With ours, it reduced it to 0.5 bushel.

“Farmers can see the cutter bar is way cleaner. In cereal there’s a benefit. If it (the crop) is really short, in dry years or where it’s dried out, it feeds better. So you don’t need the reel so much. But the big difference is in canola, lentils, lighter crops.”

A narrow four-inch side panel also helps reduce loss in canola when fitted with a vertical cutter bar.

The TruFlex Razor headers use a three-section design that allows for each wing to flex 26.5 to 36 inches, depending on the working width. Each wing can pivot four degrees up and five degrees down.

Models equipped with the flexible cutter bar option get another six inches of flex there, for a total 42 inches of ground contouring on the 45-foot model.

The cutter bar height is controlled hydraulically and can be set to automatically contour to the terrain, causing the combine to raise or lower the feeder house to maintain a consistent cutting height.

“It has hydraulic gauge wheels,” Haas says. “So if you calibrate this header on your combine it will talk. Our header tells the combine what to do, lift the feeder house up, down, raise it (the header wings) left, right. If you drive in ditches or in sloughs you will have a constantly perfect height on your cutter bar — so it doesn’t dig into the dirt. On headlands you can manually lift one wing up (to clear ground obstacles).”

All hydraulic systems on the header are self-contained. The header only requires the standard PTO drive from the combine to operate its systems.

“The hydraulic pump and oil tank, everything is on the header,” he adds. “The gearbox is a high-end build. Everything is hydraulic on this header, so if the cutter bar hits something, it doesn’t break. It stops. If something gets blocked, the relief block for the oil will open and not break or damage anything. It will just stop.”

READ MORE: Geringhoff partners with Agco

The TruFlex Razor header is available in 35-, 40- and 45-foot widths, but Haas says other models are now in field trials that will eventually offer more cutting width choices. And Geringhoff headers are compatible with all combine brands.

“We can put this header on all varieties of combines,” he said. “It doesn’t matter if it’s green, yellow, red or black, whatever.”

Geringhoff headers come with a standard two-year factory warranty, but a longer five-year warranty option is available. The company now has a warehouse in Saskatoon to supply Western Canada.