Ever since engineers turned their attention to designing the perfect farm tractor, the challenge has been the same — how to turn engine horsepower into traction at the wheels in the most efficient way. That led to some interesting designs in the early 1900s when tractors were starting to get serious attention from farmers looking to replace horses in the fields.

The exponential growth in the size and scale of ag machines made delivering maximum traction even more challenging. And the increased soil compaction caused by heavy machine traffic creates one more problem.

In the 1970s, as bigger, more powerful tractors appeared on drawing boards, that concern about developing enough traction led to several creative tractor configurations. Here’s a look at some of the solutions engineers came up with.

First, how do you transfer 1,100 engine horsepower to the ground? That’s what engineers who created the one-of-a-kind Big Bud 747 model in the 1970s had to figure out. It had a mammoth 16-cylinder Detroit Diesel under the hood.

The 747 still exists, but it had been sidelined for several years due to a lack of adequate replacement tires. The manufacturer that created the specialty tires for it when it was first built had since ceased operations, and the original tires had deteriorated over the years. It wasn’t until Titan Tire created the LSW 1400/30R46 ag tires that the 747 could get back to work. A set of the tires was installed on the Big Bud last year in a well-publicized event.

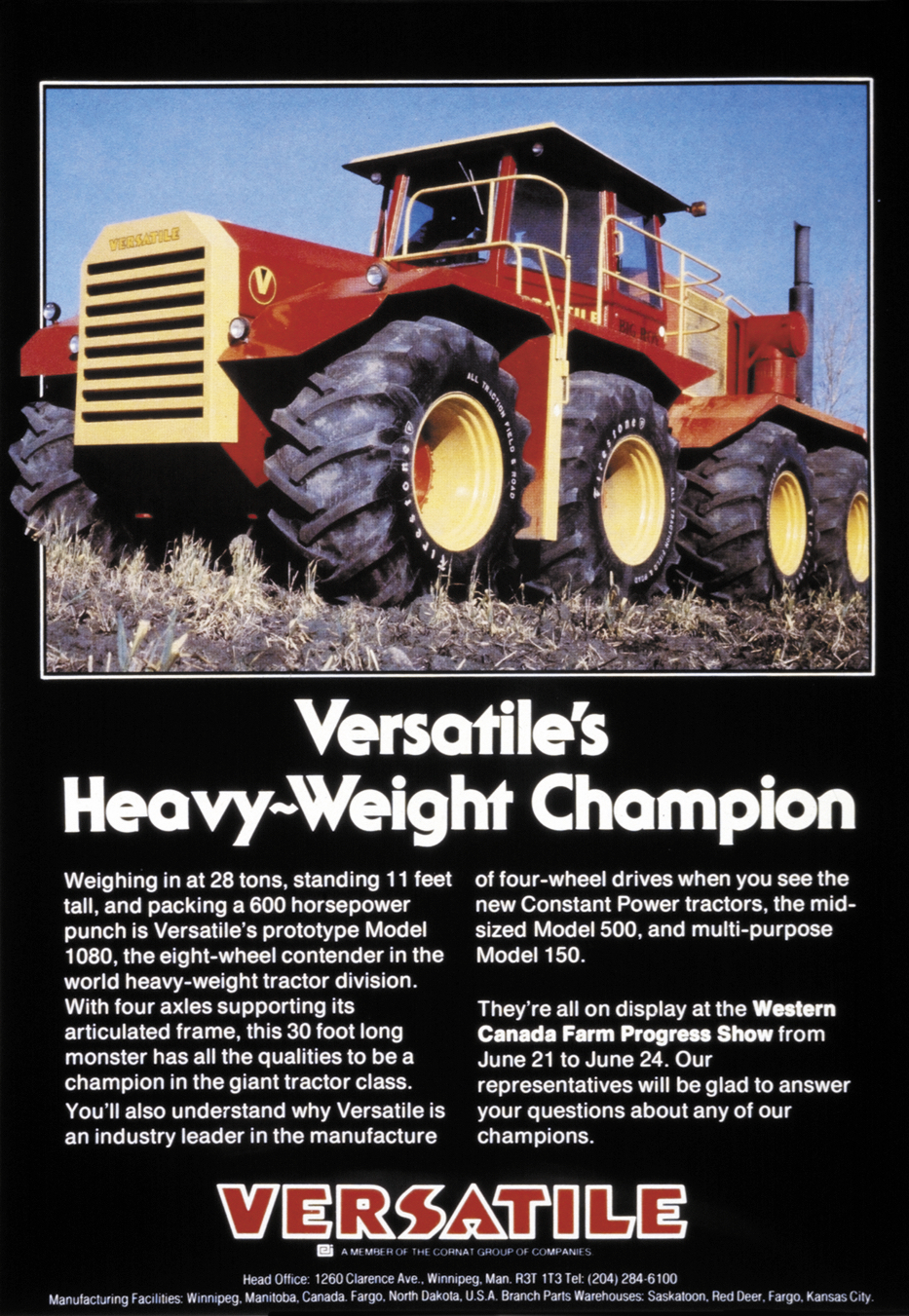

The lack of large enough tires to deliver extremely powerful tractor power to the ground was part of the reason the designer of Versatile’s famous Big Roy concept tractor (another design from the ’70s) opted for an eight-wheel drive configuration. Despite all that rubber, the eight-wheel drive concept proved to be a nonstarter. The high torque transmitted through the driveline wanted to twist the axles and lift alternating tires off the ground, which meant it suffered from a lack of traction despite all of those big wheels.

Versatile had experimented with an articulated six-wheel drive tractor before building Big Roy, but those familiar with its field trials said it was difficult to steer through turns. That’s because the rear section of the tractor wanted to push straight ahead, often causing the beads of the front tires to break free from the rims and deflating them.

Other brands experimented with six-wheel drive over the years as well. Finland’s Valtra produced a model in the 1970s with that design, which saw limited production. In 2007, AGCO, which now owns Valtra, displayed a much more powerful concept six-wheel drive tractor, the Trisix, at Agritechnica in Germany. However, it used a rigid-frame design.

The Trisix (see photo at top) was built as part of AGCO’s Fendt brand. It was 22 feet long and could produce 540 horsepower as well as achieve road speeds of 40 kilometres per hour. It also boasted a continuously variable transmission.

It was inevitable that engineers would eventually look to tracks as standard equipment for farm tractors. And although tracked machines had been tried in the distant past without catching on, the introduction of rubber belt tracks made the concept workable — and popular. When it came to traction and floatation, they outperformed standard ag tires.

However, the change from bias to radial tires narrowed the performance gap between tires and tracks. Recent introductions of VF radial tires have closed that gap even further.

Now, with the widespread use of autonomous machines on the near horizon, industry insiders expect that technology will result in larger numbers of smaller, lighter machines taking the place of today’s heavy, high-horsepower tractors. Combined with tracks or VF radial tires, soil compaction caused by autonomous machine field traffic may become a much smaller problem to deal with in the future.