In this second instalment of our sprayer technology series, we take a look at the latest Patriot models introduced by Case IH last year: the 50 series.

“With the introduction of the Patriot 50 series, we took the opportunity to start with a clean sheet of paper,” says Mark Burns, application equipment marketing manager at Case IH. “The trailing link suspension we’d been using since the early ’90s has served well. But as equipment has gotten bigger, as tank size has become larger, there really was an opportunity to look at how we provide better ride quality. On the 50 series, there is a complete, ground-up redesign of our suspension. The new design has gone with a four-bar link and the dampening is done via an airbag and shock absorber, so we’re able to adjust dampening based on load.”

They were also given a bit of a facelift with some new body styling.

Read Also

Bourgault rolls out new drill, opener and upgrades to BiC system

Bourgault in mid-January announced the release of three new products for its 2027 model year lineup: a new 50-foot drill, a new twin-shank opener and an upgraded BiC system.

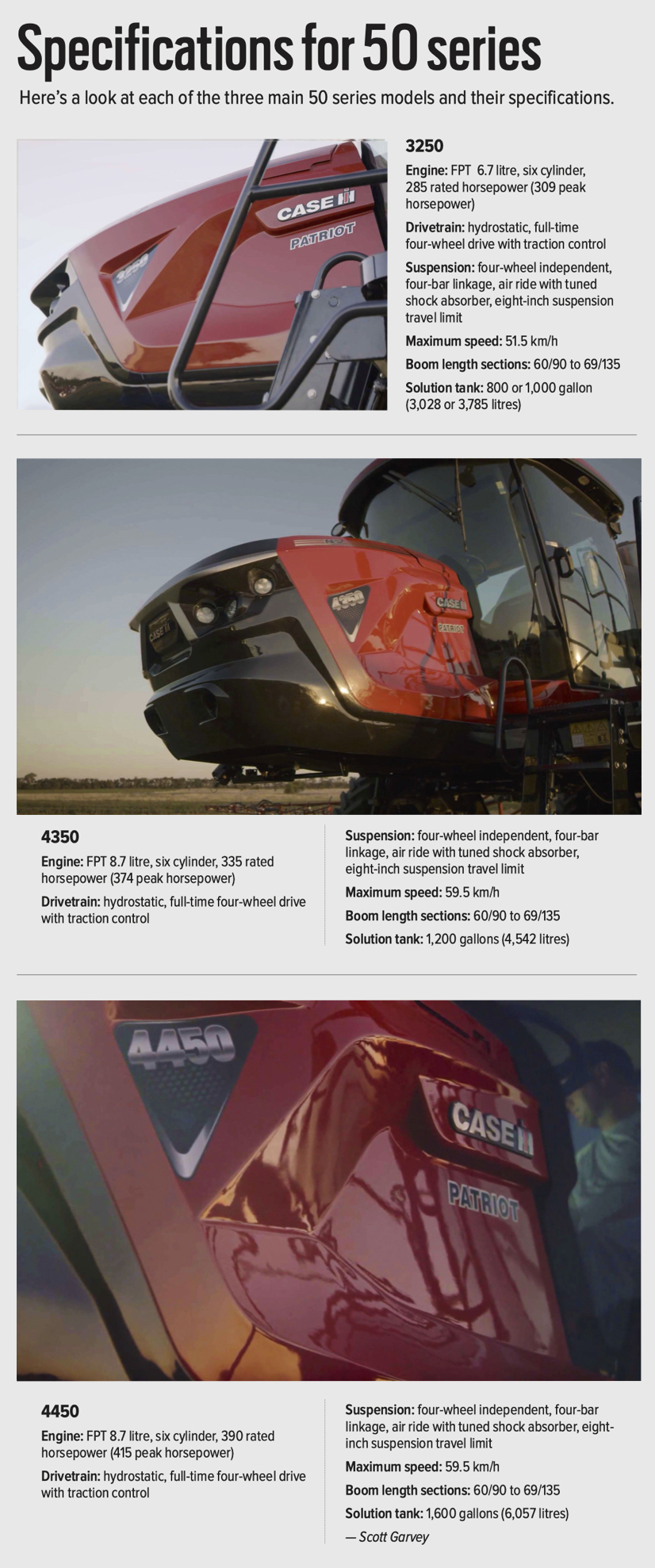

The three models (other than the smaller 2250 version, which likely won’t appeal to many Prairie growers) offer 285 to 380 horsepower under their hoods and tank sizes of 800 to 1,600 gallons (3,028 to 6,057 litres). Underbody clearance on the two smaller Patriots is 53 inches (135 centimetres), while the largest model pushes that up to 56 inches (142 centimetres).

AFS Pro 1200 monitor

Inside the cab, operators could find things a little less cluttered with just the new AFS Pro 1200 monitor and new A-pillar-mounted machine data screen to compete for the operator’s attention.

“One of the neat things we have coming to market is the single display, using the new AFS Pro 1200 monitor,” says Casey Mack, AFS marketing manager at Case IH. “A lot of our guys are used to a dual display in the cab. We’re still going to have that functionality with the Raven Viper 4, but now we’re going to present the single display solution in some models.

“Being able to capture all of our as-applied maps, all of our data going through the field that our customers are used to, we now have the ability to do that with the Pro 1200, but with the API that we have with Slingshot, we have the ability to transfer that information to the cloud and back and forth between the two digital worlds.”

And for pre-season planning, Case IH’s AFS Connect Cloud platform will allow producers to feed in other data they may have already collected, so all of a grower’s field information is organized and co-ordinated in one place.

“You can actually take some of your old data and read it into AFS Connect as well, Mack says.

“There’s no real size limit for the number of files you can store in there.

“To be able to save that information and compare pass to pass to see each season, year over year with all that data, they (producers) can make some justifiable decisions about their operations’ future needs. It drives a lot of value back to the customer so they can do some planning.

“About every competitor’s files — Raven, John Deere — all those files can be read into Case IH as as-applied maps.”

Accusync

And while data can be shared between the two digital systems, AFS Connect and Slingshot, the Accusync feature allows Case IH machines working together in the field to share data too.

“Accusync is when you have multiple machines running in the same field, they’re sharing data back and forth in near real time,” Mack adds. “As one sprayer sprays over a certain spot, it will send that coverage information to the other sprayer. So, as the second sprayer comes over an area that’s already covered, the nozzles will shut off. It’ll turn the nozzles on and off where they need to be, to save from over or underapplying.

“There is also the ability to share guidance lines back and forth. In the old world, we’d have to take a thumb drive between the monitors. Now we have the ability to share that over the air. So, everybody is on the same page throughout the field.”

Both the Case IH digital technology offerings also allow for remote diagnostics.

“With the AFS Connect or Raven Slingshot, depending how the machine is set up, we can get technicians to remote in and view, even in the case of the Slingshot, to change settings or help troubleshoot,” notes Burns.

When it comes to AI-supported spot spraying in green-on-brown and green-on-green applications, Case IH doesn’t have a system on the market yet that is capable of that, but it does have one in field trials.

“The targeted spray applications are gaining a lot of buzz in the marketplace, Burns acknowledges. “CNH Industrial will be working along with One Smart Spray, which is the joint venture of Bosch and BASF. We’re relatively new within that arrangement, and as work develops, we’re going to bring those solutions forward.”

Raven autonomy

When it comes to autonomy, Case IH made an eye-opening announcement last year with the introduction of the fully autonomous Trident dry and liquid applicators, a sister line to the Patriot sprayers. That somewhat unexpected commercial introduction of an autonomous machine was accelerated by the takeover of Raven Technologies by CNH Industrial, Case IH’s parent company. It brought immediate access to the autonomous systems Raven had been developing, which helped accelerate the introduction of new features on CNH’s brands.

“As far as the Trident with the Raven autonomy, that was a nice platform to provide a quick solution to the marketplace when it comes to autonomous vehicles,” explains Burns.

However, as of yet, there hasn’t been any official word on when, or if, that autonomy will migrate over to the Patriot line. But aspects of autonomy have found their way into the list of advanced features built into the Patriot, such as individual nozzle control to prevent overlaps and Accuturn, which automates end-of-row turns.

“As we get to the end of the row, we can populate the turn at the end of the field, so the driver doesn’t have to touch the steering wheel to make that turn,” says Mack. “There’s no guesswork to try and make an exact turn. The sprayer just basically takes over and does it itself.”

Finding ways to integrate autonomous elements is something engineers are doing across all of the company’s equipment lines.

“Looking at where autonomy could benefit the customer base the most, drawn implements are really starting to gain some attention as far as autonomous development,” continues Burns. “With that said, we do have some automation features that come along in the application platform within the Patriot sprayer. We have a host of features that really help make the life of the operator much simpler.”

Purchasing a new patriot sprayer brings not only the digital technology built into them, it also includes an automatic five-year subscription to AFS Connect, the Cloud platform that supports the brand’s digital features.

“That includes all of your data, all of your as-applied (maps),” says Mack. “Everything goes to the cloud and goes to a site you can go into, create your own username and password to have your own account.”