Six years ago, Case IH dazzled the crowd at the United States’ Farm Progress Show held in Boone, Iowa, with its concept fully autonomous, cabless Magnum tractor. That year, the Case IH exhibit attracted very large crowds on each day of the event, as everyone vied for a close-up look at the robotic Magnum.

This year, the brand was back at the same show with another autonomous machine, the Trident 5550 applicator. But this time it’s not a concept machine. Case IH expects the robotic Trident to be released to North American buyers in 2023, albeit in limited numbers.

According to Case IH, the development of the fully autonomous Trident is a direct result of the recent acquisition of Raven Industries by Case IH’s parent company, CNH Industrial. That move made a collaboration possible, where Raven provided the digital technology and Case IH supplied the iron and sheet metal.

Read Also

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

“This is a significant milestone in our accelerated product development efforts between Case IH and Raven, highlighting our intense collaboration and robust product innovation following CNH Industrial’s acquisition of Raven in late 2021,” said Scott Harris, Case IH global brand president.

Unveiling the Trident at the 2022 Farm Progress Show in Iowa this past summer allowed the brand to give farmers their first look at it and see it at work during in-field demonstrations on the showgrounds.

Case IH says after if first showed the concept autonomous Magnum to farmers back in 2016, it did a lot of research to see what jobs farmers would be most comfortable assigning to an autonomous machine. Dry product spreading came out as one of the most popular answers, so the brand focused its development efforts on the Trident, making that its first fully autonomous machine for commercial market release.

Reliable enough for marketplace

Raven is fully confident in the software it has created for guidance, steering, propulsion control, perception and path planning, and it believes the Trident is now reliable enough for the marketplace. Once farmers become familiar with autonomous machines like the Trident, they’ll be ready and eager to adopt even more robotic machines into farm operations in the future, say companies like Raven.

“The core of today’s ag tech is rooted in Raven’s customer-centric approach — simplifying farming processes to gain tremendous efficiencies,” said Eric Shuman, Raven’s general manager. “This integrated solution empowers customers to make their operations even more efficient, encouraging them to thoughtfully adopt increasing levels of automation and autonomy.”

Like most of the other autonomous machines now steadily popping up at farm shows, the Trident can be managed from a mobile device, allowing operators to use those devices to plan and complete an entire field operation based on mapped field boundaries.

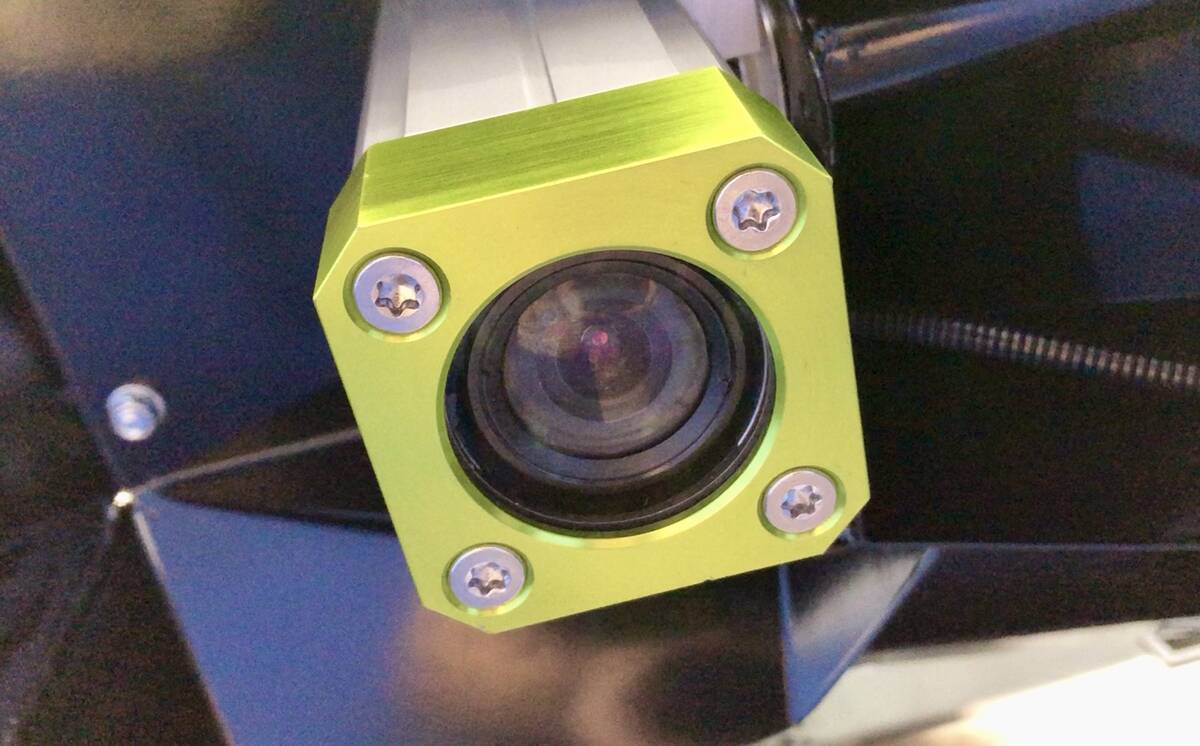

The Raven Autonomy perception system used in the Trident relies on a series of cameras and a radar system to sense a 360-degree environment around the machine, looking for obstacles and motion while operating. Artificial intelligence allows Raven’s perception controller to process and interpret the continuous stream of images to detect obstacles. A remote operator can view the camera images from the Trident through a mobile device at any time.

If an obstacle is detected, the machine will safely come to a stop and an alert will pop up on the operator’s mobile device. From there, the operator can evaluate the situation and determine how to remedy the problem. A variety of machine tasks and functions can also be viewed remotely, including fuel and DEF levels, speed, engine r.p.m., bin level status, universal terminal information and diagnostic trouble codes.

“The Raven Autonomy perception system provides an advanced, reliable solution for autonomous operation and is tailored specifically for the spreading application with a self-propelled machine,” Shuman said.

The autonomous Trident system allows for one or more driverless machines to operate in the same field without an operator present in the cab. And Case IH says the accuracy of computer control allows for the best possible spreading consistency by eliminating any human error.

Raven says it continues to focus on improving its “data sets,” allowing the artificial intelligence the autonomous system relies on to continue to learn more. The development program has now expanded to a location at Scottsdale, Ariz., providing the engineering team with direct access to two local testing sites. The company says that allows for more rapid integration and testing capabilities.

Case IH says consumers should consider the new Trident just the first of several fully autonomous machines to eventually come from the brand, although the time frame for other introductions hasn’t been revealed just yet.

“This is the first of many integrations that automate the established iron platforms of Case IH as we continue to craft a fully autonomous crop production cycle,” said Harris.