Removing excess water is the big payoff for tile drainage. Submerged fields and saturated soils can slash yields, cause salinity problems and even spell the loss of the entire crop, if it’s bad enough.

However, it is not an inexpensive fix, nor is it a simple solution, and it won’t work for every farm. That’s why farmers and agronomists need to do their homework and be mindful of important considerations when deciding whether tile drainage is a good fit.

How tile drainage works

Read Also

Are enhanced efficiency fertilizers the right fit for your fields?

Enhanced efficiency fertilizers have been available for years now, but their uptake among farmers depends on environmental as well as logistical needs.

Essentially, tile drainage works by removing water that exceeds a field’s water-holding capacity. It does this by lowering the water table.

A typical tile drainage system has three components:

- Lateral lines of perforated pipe that collect excess water from a field;

- Tile mains or headers that transport that water below ground; and

- Outlets operated by gravity or mechanical means that pump the water into a ditch or other collection area.

Drainage can be installed in different ways. One is through pattern tiling, where every acre of a field is tiled, and another is through selective tiling, which involves tiling only certain areas of a field.

Tile drainage can be also used to artificially set water levels in a field, which ensures water is available when needed to nourish crops and removed when there’s too much.

This is done through controlled tile drainage systems. These require water storage areas such as holding ponds, as well as additional infrastructure, such as risers, gates and valves that regulate water flow within the system.

Lay of the land

A key factor when deciding whether tile drainage is a good fit for farms is the suitability of the land itself.

Tile drainage is generally more straightforward and therefore simpler to install on level or gently sloping farmland. However, there are times when tile drainage can be a good solution for fixing water problems in areas that are anything but flat.

That’s been the case for Dustin Williams, who farms near Souris, Man. In an interview with Grainews, Williams described his land as particularly well-suited for tile drainage. It has a fair amount of elevation and slope in spots that cause problems with saturated soils and water ponding in low areas. Because the soil is sandy, water can move through it relatively quickly, which can cause groundwater deficits in drier conditions.

Williams opted to start installing tile drainage on his farm in 2020, after a two-day downpour drowned one of his canola fields the previous year.

“It just rotted out,” Williams said, adding it was the fourth time in 10 years the low-lying field had produced either a suboptimal crop or no crop at all.

“It was just due to the water ponding and soil staying saturated for too long. We made the decision to start improving the land.”

Williams contracted NextGen Drainage Solutions, a tiling company in Pilot Mound, Man., to install 150 acres of subsurface tile in the problem field. Waterlogging wasn’t an issue after that, he said, adding he plans to add drainage tiles to more acres in the coming years.

Fix for saline soils

Farms with salinity problems are another place where tile drainage, in the right circumstances, can work wonders.

Saline soils can have quite a negative effect on crops by reducing root development, plant growth and ultimately yield. In severe cases, they can kill crops and make the land unsuitable for agriculture.

By removing excess water and lowering the water table, tile drainage systems can prevent salts from being drawn into the rooting zone.

Olaf Boettcher, president of Saskatoon-based Precision Drainage Solutions, has been installing tile on Saskatchewan farms since 2017. He said in a recent interview that soil salinity is a problem across Western Canada and a big driver behind the growing interest in tile drainage.

For many of Boettcher’s customers, high water tables have contributed to waterlogged fields and made flooding more likely, and also led to large salt accumulations in the soil. Tile drainage addresses both problems by lowering the water table.

“High water tables drive the salts up. And then, even in the dry periods or later on in the growing season, that creates problems,” Boettcher said. “A lot of guys are looking at tile drainage for that reason.”

According to Boettcher, tile drainage works best in areas with higher rainfall because there is more excess water, which flushes salts downward in the soil profile.

Boettcher said many of his customers stick with their tile drainage projects even during drought years because they see it as a long-term solution to salinity problems.

Irrigation recharges groundwater in fields and can cause water tables — and sometimes salinization — to rise. This is another area where tile drainage can address problems.

Craig Millar farms 5,000 acres of dryland and irrigated grains and oilseeds near Birsay, Sask. The farm is in the Luck Lake Irrigation District near the Diefenbaker Lake reservoir in south-central Saskatchewan.

Millar said he opted to have drainage tiles installed on 30 acres under one irrigation pivot a few years ago. He hoped it would stop the spread of soil salinity that seemed to expand a bit every year, and he’s been pleased with the results.

“We were pleasantly surprised to see after a few growing seasons that the saline area is actually decreasing in size,” Millar said. “The tile drainage is helping carry the salts away.”

He noted that nearly all the land under irrigation pivots on his farm would likely benefit from some amount of tile drainage. Millar now has his own tile plow, with which he plans to treat more problem spots under more acres in the years to come.

“I’m really excited about tile drainage. I believe it could benefit much of the land within the Luck Lake Irrigation District.”

Aaron Hargreaves, a Manitoba producer, said tile drainage could be the best tool in the toolbox for managing saline soil in fields.

As part of a panel discussion at the 2024 Manitoba Ag Days, Hargreaves spoke about how he and his farming partners tried several practices to fix salinity issues on their 17,000-acre operation near Brandon.

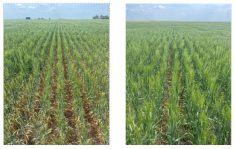

None were as effective as tile drainage, which he said has had a positive effect on many problem fields. Yields have increased dramatically, and the reduced saline has allowed the farm to plant crops that would have fared poorly in the past. One of those crops is pinto beans.

“Pinto beans are extremely sensitive to salinity, but they are growing well in that area of the farm now. We couldn’t even grow canola in the field four or five years ago,” said Hargreaves.

He offered this piece of advice to Prairie producers who have installed tile drainage or are considering it: Be patient.

“It can take time (to have an effect). In an area like Nesbitt (about 30 km south of Brandon), we’ll see results lots of times in one or two years to fix the spots where the salinity isn’t too strong. Where it’s really bad, it’s still going to take a long time.”

Hargreaves said one unexpected benefit of tiling has been the “huge” effect on weed control, especially kochia. The invasive tumbleweed thrives on saline soils.

“Roundup-resistant kochia is prevalent in our area. In a tiled area in our field, we are reducing the amount of kochia in that field by 75 to 90 per cent easy. It’s a hugely effective tool in the management of kochia,” said Hargreaves.

More benefits of tile drainage

A group of farmers interviewed by last fall identified fixing soil salinity as a key benefit of tile drainage, but listed numerous others.

A big one was boosting a farmer’s bottom line. They noted improved soil and field conditions should translate into higher yields and improved crop quality.

Also on their list:

- A tile drainage project removes standing water or waterlogged conditions, making it possible to put more acres into production.

- Tile drainage can improve the timeliness of field operations. Farmers can seed or combine sooner, for example, after heavy rain.

- With tile drainage, farmers are better equipped to manage through extreme weather conditions, providing important peace of mind.

- In some cases, municipalities might see reduced damage to infrastructure, such as roads, because flooding conditions are better managed or prevented.

One of the producers, Owen Orsak, said improved efficiency is the greatest benefit he’s seen after installing tile drainage on his farm in southwest Manitoba.

“It is more efficient time-wise, fuel-wise and input-wise. I’m not steering around potholes to get the field seeded. I’m not spending three hours trying to get the seed drill unstuck because the operator got too close to a wet spot, and I’m not trying to turn the sprayer around these wet spots and creating a lot of overlap,” said Orsak.

“It used to be a 260-acre field with 28 wet spots, so I would seed 240 acres and probably combine 220 acres. Now I can seed 260 acres and combine 260 acres.”

Gord Unger is plant manager at Advanced Drainage Systems, a tile manufacturing plant in Carman, Man. As acreage managed under tile drainage systems has grown over the past 25 years since the plant was built in Manitoba, he’s seen how it can make it easier for producers to work their fields and reduce wear and tear on farm machinery.

“They don’t have to go around wet holes in the fields (and) because the soil is easier to till, it’s easier on the equipment and it uses less fuel,” he said.

According to Boettcher, an important agronomic benefit of tile drainage is that it reduces surface runoff and can increase water filtration.

“It improves your soil tilth and soil structure, so your roots go deeper, sooner in the season and make more (drought-resistant) plants. You get a deep root system early and it gives the plant access to more nutrients and water,” said Boettcher.

Ed Froese, owner-operator of Innovative Agri Tiling, a tile installation company in Reinfeld, Man., noted drainage tiles installed in the right areas and at the right depth remove excess water that is harmful to root growth but will still maintain adequate soil moisture levels.

Froese said by regulating water levels in a field this way, tile drainage enables young plants to develop good root systems and become better equipped to deal with potential stressors such as disease and drought. It also helps crops grow longer roots that can tap into a lower water table during the hot summer months.

Tile drainage economics

Many believe the biggest upside of tile drainage is improved productivity. Higher yields usually mean more money in the bank for producers.

Unger said he believes that on average, farmers can expect to see about a 20 per cent yield improvement on tiled land.

Some studies from Iowa, Ohio and Ontario have shown increases in yield of four to 45 per cent for corn and soybeans grown in fields with subsurface drainage. Another study in Minnesota showed yield increases of 10 to 30 bushels per acre for corn and four to 15 bushels per acre for soybeans.

Williams said it didn’t take long for him to realize the value of tile drainage once he started using it on his farm. All he had to do was look at the yield monitor on his combine.

“With my land, it’s very apparent where I have water issues, and the more I watch my yield maps, the more I realize that the vast majority of my (yield) losses in a given year are actually because of poor water management,” he said.

“I know that it’s because water is sitting here. It’s causing salinity, it’s causing kochia, it’s causing a decline in plant health, an increase in root rots — all of those things. They all have a big influence on the final numbers.”

Tile drainage can help farmers looking to increase productivity and profitability without expanding the land base. Producers can increase the number of arable acres within their farms rather than buying additional farmland.

Froese said that is the case for many of his customers, who are opting to improve their existing land rather than purchasing more acres because “land prices have jumped up so high.”

One way a producer or agronomist can determine whether tile drainage will increase profitability by identifying and assessing the main yield constraints on the farm.

If the biggest yield-limiting factor is something like disease, saline soils, delays in planting or a lower-than-expected grade, for example, that’s often the result of not enough water or too much of it at the wrong time. That is the central problem tile drainage is meant to fix.

David Whetter, a Manitoba soil scientist and agricultural-environmental consultant, touched on the economic benefits of tile drainage during a seminar at 2024 Manitoba Ag Days show in Brandon, Man. He said it’s hard to quantify the effect tile drainage can have on yields in the Canadian Prairies because there’s so little regionally specific data.

“A sad story is that we don’t have a lot of good local data, at least not that’s out in that public realm. We have to lean on other regions to look at data, and even then, there’s not a lot of data out there. Manitoba or Prairie region results are really needed here,” said Whetter.

The biggest downside of tile drainage is cost. It can carry a hefty price tag. However, costs vary widely depending on the size and complexity of projects, as well as a farm’s terrain and the type of tiling being installed.

Unger said the cost of installing tiling systems on farmland typically runs somewhere between $1,000 and $1,500 per acre. Froese pegged the average cost at about $1,200 per acre.

Pattern tiling typically costs more to install than selective tiling systems because it involves a larger area. According to Hargreaves, its advantages include allowing a field to be seeded earlier, leading to more uniform crop maturity. Machinery is also less likely to get stuck on hilltops.

In most years, farmers will find selective tiling is generally adequate in fields that have good natural drainage, he added. Because the overall cost per field is usually less with selective tiling, he also believes it can provide a faster return on investment.

Froese said tile drainage systems generally cost more when lift systems are needed to transport excess water from fields lacking natural drainage.

It’s generally less expensive to install drainage tiles during dry periods. There’s no mucking around and soils are generally easier to work with.

As far as return on investment for tile drainage systems, it differs from farm to farm. Unger said he believes it has generally improved with rising prices for agricultural land.

“They used to say the number on average was 10 years to pay the cost for drainage tiling back,” he said. “But as land prices have increased, and as farmers are also finding they can be more productive with their land, that time frame has definitely shrunk. I know of some who have paid their tiling bill back in three to four years.”

Unger added that because tile drainage is such a large capital expense, most farmers will start with one field or area that would benefit the most and then add acres over time rather than going all-in right away.

“They’ll do a certain area that’s giving them trouble because it’s so wet and they’re not getting any yield on it. They might start with that, and then after that, they’re kind of hooked. They will keep going for the most part, adding more and more acres every year.”

Planning tile drainage projects

Deciding whether tile drainage makes financial sense is an important first step, but there are numerous other factors to consider. Whetter said that’s why it’s important to do the homework before embarking on any tile drainage project.

“It’s a big investment and producers know their land the best. My advice is to make sure that you’re part of the design process in terms of that kind of gut feel. Does the design make sense? Are the right areas being drained? Seek advice where there’s any uncertainty just to make sure you can optimize your investment.”

According to Whetter, a key consideration should be the drainage coefficient — that is, the number that describes the maximum rate of water removal for which a tile is designed.

For example, a drainage coefficient of a quarter inch of excess water in a day is the typical design standard. What this means is if there’s one-inch excess rainfall event, it will take four days on average to remove that excess water from a field. The higher the drainage coefficient, the higher the cost of the drainage system.

Whetter said another design consideration is depth of tile or pipe. A minimum depth of 2.5 feet is typically required to maintain pipe integrity, he said. In Manitoba, for example, tiles are typically installed at three to four feet.

It’s also important to consider any restrictive layers in the soil, Whetter said. This can include areas where sand is located on top of clay, or where there is significant compaction that can make installation more difficult and affect tile performance.

In some parts of the Prairies, farmers sometimes must contend with excess water and drought in the same growing season. Whetter said that’s why getting the water table at just the right height is so important with a tile system.

“The golden rule is to drain just enough water for crop growth but not a drop more,” Whetter said, adding variable soil landscapes throughout Western Canada also complicate decisions around tile drainage.

“The takeaway here is the snowflake analogy. Every field is unique, and it really requires a field-specific solution, particularly when we get into these variable landscapes.”

Hargreaves said he and his partners found that in cases where selective tiling was installed, narrower spacing of the perforated pipe is more effective. In most cases they have spaced the pipes 25 feet apart rather than the standard 50 feet.

He also suggested it can be better to err on the side of caution when installing tile drainage. In instances where a saline problem in a field is quite narrow, for instance, he recommended that tiling be extended well past the outer edge.

“We found it definitely works better, way better, if you go well beyond where you see crop loss to make it work as best you can,” said Hargreaves.

Boettcher stressed water from a drainage tile system must have someplace to go, so access to a suitable outlet, such as a natural waterway, ditch or on-farm retention pond, is a must. If a farm lacks an outlet, or if it’s near a protected wetland or some other area that makes drainage problematic, it’s probably not a good candidate for tile drainage.

Permitting

Proper planning also includes ensuring projects don’t just transfer a water problem to a downstream neighbour or have an adverse effect on the environment or wildlife habitat.

Consider where the water will drain and who will be affected. Also note what water bodies will be affected. This is where permitting comes in.

Brandon Leask is an agricultural water engineer with Alberta Agriculture and Forestry who provides technical assistance with respect to water management and helps educate farmers about provincial regulations related to tile drainage projects.

In an interview with Grainews, Leask noted Alberta has fairly stringent regulations around agricultural tile drainage, so he recommends that producers seek the services of a tiling installer.

“It’s not a minor process unless you’re really knowledgeable about it. Hire a contractor to assess the situation for you, to design it for you, to apply for the approvals and (do) everything else for you, because it’s not a simple process,” Leask said. “There’s a lot of pieces in the puzzle.”

Boettcher said it’s important for farmers and agronomists planning tile drainage projects to familiarize themselves with water stewardship regulations. They can be complex, he said, which is why many farmers prefer to have a professional tile installer deal with the permit process.

Permits are always an important consideration in Saskatchewan, he added, especially in certain areas such as the Quill Lakes region, where risk assessments can make it more difficult to get regulatory approval.

“We don’t really work in some of those areas because it’s pretty hard to get permits there,” he said.

To take the CEU quiz for this article, CLICK HERE.

MORE INFO: Controlled tiling systems

In a conventional tile drainage system, drainage occurs directly from the tiles to a downstream water body. In controlled tile drainage, the flow of water is controlled by mechanisms installed at the system’s drainage outlets.

Controlled tile drainage is becoming a more popular practice that can reduce agricultural run-off of nitrogen and phosphorus via tile drains, and provide agronomic and financial benefits to producers. Some research from Ontario and the United States suggests controlled tile drainage can increase corn and soybean yields by three to 11 percent.

A 2017 research paper from the Ontario Soil and Crop Improvement Association stated controlled tile drainage should be considered a risk mitigation practice that can help protect producers from crop losses and could potentially stabilize yields over the long term.

Controlled tile drainage systems are more expensive to install and operate, however. The additional cost of controlled tile drainage depends upon the number of control structures per field. Additional costs can include lift stations to move subsurface water from a lower to higher elevation when natural gravity flow isn’t sufficient.

Hargreaves noted lift stations are expensive and most require an electrical source to operate. They also need to be regularly monitored and serviced.

“They increase the cost of the project a lot and sometimes that makes it not worth doing. If you’re just trying to do a 10-acre low area, it costs $40,000 or $50,000 to put in a lift station, plus the tile. Your costs start to go pretty darn high.”

Some jurisdictions offer financial incentives for installing controlled tile drainage systems. Under Manitoba’s Ag Action program, for example, controlled tile drainage qualifies as a beneficial management practice and is eligible for taxpayer support. If a farmer completes an environmental farm plan, the province will share the cost of installing control structures for a tile drainage system to a maximum of $50,000.

MORE INFO: DIY tile drainage

Gord Unger, plant manager at Advanced Drainage Systems, urges farmers to carefully consider what’s involved in installing tile drainage if they’re thinking about doing it themselves. He knows farmers who bought their own plows to install tile and have had great results, but he’s aware of other instances where it has gone the other way.

“There are so many things that someone would have to know to install their own tiling system,” he said. “You have to make sure to get everything right. You only get one shot at doing this, because you can’t dig it out and redo it.”

Unger said if slopes aren’t calculated correctly, for example, subsurface tiles may not drain the right way. He also noted it’s important to ensure rolls of drainage tile aren’t stretched too far during installation.

“Once the tile is stretched, that makes it soft and it will collapse,” he said.

Another key consideration around DIY tiling is time. Installation is typically done in spring or fall but that’s when farmers are busy seeding or harvesting.

“When farmers consider this, many realize they don’t have time for that and they’ll hire someone else to do it,” said Unger. “There’s just too much other stuff going on the farm to wait for a time when they can to do it themselves.”