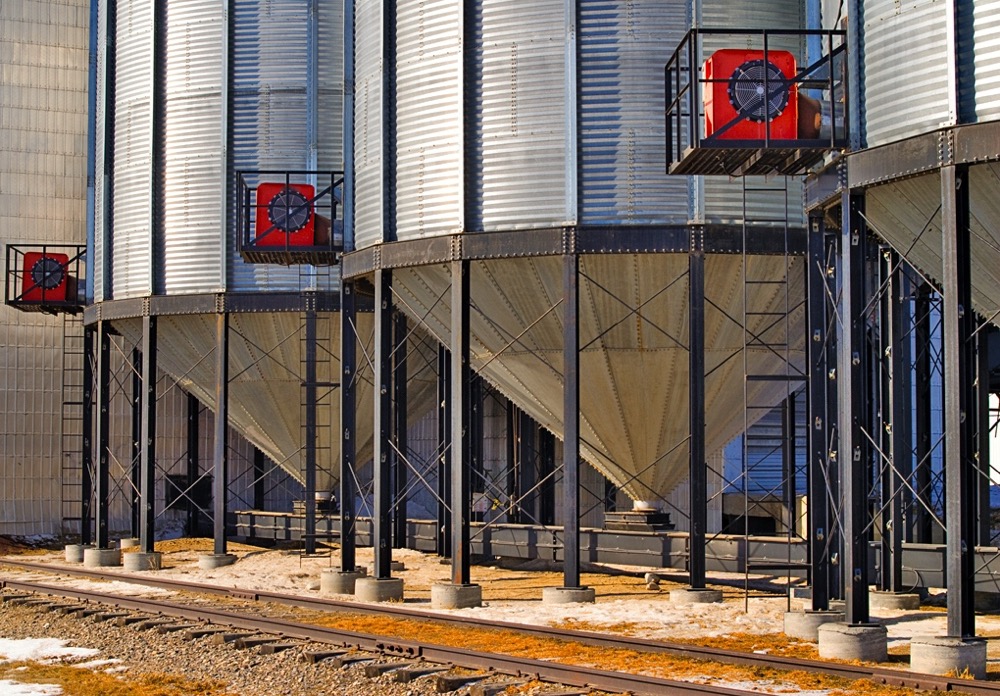

With more large bins on the farm, safe grain storage has become more important. And keeping grain from heating or spoiling is more complicated than it would seem.

“The chance of spoilage really depends on two things. It’s both temperature and moisture,” said Lorne Grieger, the Prairie Agriculture Machinery Institute (PAMI) vice president for Manitoba operations at CropConnect in Winnipeg in February.

When you’re pushing air through the grain in the bin, the greater the difference between the air outside and the grain in the bin, “the greater the effect on the grain, the greater the moisture removal.”

If you’re bringing in grain at a high temperature or a high moisture level, storage will be risky. “For safe storage conditions, 15 C is kind of that temperature that you want to shoot for, for either your cereals or your oilseeds.”

Greiger described safe storage as a two-step process. The first step is to even out the temperature in the bin. Aeration, Grieger says, “is essentially cooling.”

The recommended airflow rate to remove temperature variation is 0.1 to 0.2 cubic feet per minute per bushel (cfm/bu.). “At the recommended air flow rate, it takes about eight days to get the bin to equalize.” That is, about 200 hours of drying.

The next step is removing the moisture in the bin, through natural air drying, or near ambient drying. For this, the recommended airflow rate is 1.2 cfm/bu., or 10 times higher than aeration.

“It’s a pretty complex relationship, but really, if the air has the capacity, it will dry as it’s going through the bin.”

At 1.0 cfm/bu., it will take seven to 14 days of continual fan operation to dry wheat from 16.5 to 14.5 per cent. “Again, it depends on ambient conditions.”

Grieger’s general recommendation: “is typically, to run your fans continuously.”

The air’s capacity

The effectiveness of aeration depends on the air’s ability to take up water. As shown in the chart, if it’s 30 C outside, with a relative humidity of 50 per cent, “the air actually has 15 grams of water in it, so it can take up another 15 g.” If your grain is tough, Greiger says, “that can really be beneficial.”

However, if the outside temperature starts to drop, the air’s capacity to hold water decreases. “That’s where the benefit of having a higher air temperature can come in.”

The equilibrium moisture content is the moisture level where your grain will stabilize, given the outside temperature and relative humidity. For example, from the chart, if the outside temperature is 15 C, with a relative humidity of 65 per cent, “if you can blow that air throughout your bin,” your grain will stabilize at 14.5 per cent moisture. If the temperature and relative humidity stayed constant, your grain would remain at 14.5 per cent moisture, whether it went in the bin with a higher or lower moisture content.

The challenge, of course, is that the temperature and relative humidity change throughout the day.

“There’s really four scenarios that we’re looking at,” Greiger said.

If you have warm air and warm grain, “that’s going to be a drying scenario.” The air can suck up a lot of moisture. “The dryer the air the better, really.”

Read Also

PMRA denies strychnine emergency use request

Emergency use of strychnine for the 2026 growing season has been denied by the Pest Management Regulatory Agency.

If you have warm air and cool grain, the grain will re-wet. Some of the water that was in the air will be released into the grain.

Cooling air and warm grain “is really good for short-term drying, until the grain cools down.”

If both the air and your grain are cool, “you might get some drying out of that, but really, the difference is so small at that point, that it’s a very slow process.”

A novel fan system

With larger bin sizes, farmers have a lot more at stake. So, Greiger said, PAMI continues to test new methods of storing grain.

In 2016, PAMI tested a novel fan control system, Aeration Master, developed by Aeration Control Australia. The Aeration Master (AM) uses the basic concepts of air temperature and relative humidity and applies them to what’s inside the bin, turning aeration fans on and off automatically, depending on outside temperature and relative humidity. “It’s a touch-based system that can control up to eight different bins at one time.”

PAMI ran a study to compare the AM fan control system with running fans continuously. They installed the system in Manitoba, east of Selkirk. For this research, PAMI installed the AM system on one bin, and used another bin as a “control,” running fans continuously. Both bins were 6,500 bushel flat-bottom bins with fully perforated floors and 7.5 hp fans.

The Australian AM system comes with its own weather station to measure outside conditions. For information about the grain inside, the AM system relies on user input — you input how much grain you’ve put in the bin, the temperature, the moisture content, the airflow rate inside the bin and your target grain moisture level. This system does not use cables to measure conditions inside the bin.

The grain in PAMI’s 2016 study went in the bins at 14 per cent moisture, and PAMI wanted to cool the grain from 23 to 17 C.

The study began on August 30, 2016. During the study, Greiger said, “we saw the temperature range from 9 to 28 C.” There was also a high variation in relative humidity over the study period, as the long weekend brought a two-day rain with almost 100 per cent humidity.

With high outside temperatures, it took quite a while to bring the grain down to 17 C.

During the 28-day study, the AM system turned the fan off and on eight times, running the fans a total of 28 hours. The continuous-fan system was turned off during the two-day rain, but otherwise ran for 124 hours during the same period.

Over the month, the AM system dropped the temperature to 19 or 20 C, but no lower. However, “because the fan was controlled,” the temperature of the AM-controlled bin was much more stable during the test period. The AM system also kept the moisture content in the bin more stable.

The lack of sensor cables means few things can go wrong with the AM system. However, because it runs on predictions based on outside air temperature, it does give users the feeling that they’re dealing with a “black box” — not knowing what’s going on inside that bin could be stressful. “You don’t have that feedback to know what’s going on with your grain,” Greiger said.

The AM system also requires more initial management. Users need to input the grain moisture and temperature when you put it in the bin. If the system has the bad information, it won’t run the fans correctly.

Over the study period, the AM system ran a lot fewer hours, which would mean lower operating costs. It also kept the grain at a more constant moisture and temperature.

“This is one test under one set of conditions,” Greiger cautioned. PAMI will be looking at the AM system further, and adding heat to the system.

Summer canola storage

This is the time of year when farmers start to have questions about summer canola storage, said Lorne Greiger, PAMI’s

VP of Manitoba operations at CropConnect 2017.

Farmers wonder if they should leave it alone, turn on their fans, or turn the canola. PAMI tested all three of these options in trials in Saskatchewan in 2014 and 2016. The canola going in to the bin was dry in both tests.

In both of these two trials, Greiger said, they found that “both the turned and aerated bins had some unstable conditions that could have resulted in spoilage.” Temperatures were more stable in the bins they left alone.

When bins are aerated, a warm front moves through. When bins are turned, as warm grain from the top funnels into the center, there is a warm core left adjacent to the cool grain.

Given the information drawn from these two bins, under these particular trial conditions, PAMI’s best advice is: “leave it alone.”