You’ve seen them lots. QR codes. Those odd-looking squares with black markings that are applied to a lot of packaging. And in recent months, you may even now have a QR code image on your cellphone to show the world proof of vaccination against the COVID-19 virus. But do those codes have a fit in daily farm life?

Ben Cavers and Willem van Staveren are southern Saskatchewan farmers who have multiple QR codes applied as stickers in their tractors, combines and field sprayers, which carry information on service procedures, basic machine operation, calibration, settings, mixing instructions and field notes specific to their farms, their equipment and their fields.

Read Also

Farm equipment market unlikely to pick up

North America’s farm machinery sales have been slow and uncertain thanks to tariffs and trade disruption. There’s not a lot of hope for change in 2026.

Cavers and Van Staveren only developed and began using this type of coding for the first time during the 2021 growing season, but for operations such as seeding, spraying and combining, for example, it beats trying to remember every last setting and chemical mixing combination, or carrying around a pocket full of papers with notes. The farmers can see the amount of information and value of the QR codes expanding with every season on their farms.

- Read more: More on QR codes

How to create QR codes

Starting at the farm office computer, you must create the information you want to store on each QR code. Once you have the information, photo or video file created, you can go to Google Drive, follow the steps to create the QR code, then store the information in folders within each QR code and, finally, print the image of the code. You need to be a bit fearless on the computer at the outset, but it is relatively easy to learn, and, best of all, it is free. It doesn’t cost anything to create a QR code. More details on that below.

Once the code is made and posted inside the tractor, sprayer or combine cab, as long as you have a smartphone, you can capture and open the QR code files that hold the information you need for a specific operation — right there in the palm of your hand. You, another member of your farm family, or a hired worker can see the specific information they need. Cavers even had one chemical retailer who specifically created a file on a chemical product with mixing instructions just so that it could be uploaded to his QR code for spraying.

“What I really like about the QR codes is all the information you need for operating that piece of equipment is right there in the cab on that QR code,” says Cavers, who is part of the family-owned Be-Ver Farms at Sedley, southeast of Regina.

“For a seeding operation, for example, I can take a hired man out to the drill and the QR code has all of the start-up procedures, the settings for different crops, seeding rates, and I can even include a short video on there of me walking through various procedures — it is all there,” says Cavers.

“Then I can leave and do something else on the farm, and if that operator has a question, he’s not held up. He can look up the information on the QR code, rather than try and reach me by phone and wait until I can get back to the field to show him something. And with three seed drills running at one time, if the operators are new or if people forget something, my phone can get pretty busy.”

Over at JVM Van Staveren Farms at Creelman, Sask., it is a similar story. There are several family members involved in the combined 22,000-acre farming operation, with numerous fields producing canola, durum and red lentils. And there is a relatively large fleet of equipment used to perform seeding, spraying and harvesting operations.

Van Staveren says it is impossible to keep track of all the details for each operation in his head, and it could require an extensive binder of information to accompany each piece of machinery.

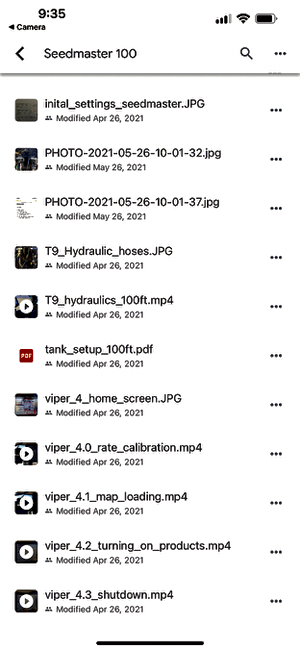

“We’re just starting with these QR codes, so we want to keep it simple,” he says. “We created a SeedMaster QR code with information on two different seeders — the 80-foot and 100-foot machines. Inside those folders is information like hydraulic settings, Viper controller settings, which controls the seeder, and pictures as well as a video walk-through of basic drill set-up.”

At harvest, the combine QR code has folders with information on different rotor and fan settings, a daily maintenance checklist for that machine, a 100-hour maintenance checklist, GPS settings and other general information.

“Sometimes it is information we might have needed to call the dealer to get the answer for,” says Van Staveren. “And that can take time. Once we have the information, now we can store it in the QR code. We can also create a folder with troubleshooting information, which may include photos or a short video.”

Van Staveren even has a QR code with the farm’s Wi-Fi password posted in the farm shop. It is a long password no one can remember, but by scanning the QR code people can access the password and sign on to Wi-Fi.

Both farmers say if they were only doing one or two jobs repeatedly, they probably wouldn’t need any notes or a QR code. However, there are multiple pieces of machinery; sometimes they only do a procedure once or twice a year; settings and controls change with each machine, each crop and with different fields; and then there may be multiple operators who aren’t familiar with machinery or procedures.

The basic operating information, settings, walk-through videos and troubleshooting information can all be included in a QR code for each machine.

Common problem on farms

The idea of using QR codes for farm information was suggested by Taylor Phillips, a Regina-based consultant who was born and raised on a Saskatchewan farm. Now, as part of his consulting services known as Producers Edge, he works with farm clients to help simplify and connect them with ag technology.

Taylor meets with farm clients at least three times a year to make, sort of, a dry run through the steps and requirements of the season ahead, such as seeding, spraying and harvesting. For example, what does the workflow look like? What problems might be encountered?

“What I was hearing from clients, and everyone was saying the same, was the challenge of keeping track of all of this information for each operation,” says Phillips. “During the first couple of weeks of the season, they will get themselves up to speed again, but the real problem is the 10 months in between … information can get forgotten or misplaced. I suggested we try QR codes as a way of keeping that information accessible.”

The idea was to create a QR code for an air seeding system, for example, and within that code are as many folders as the farmer wants, with information on operating, set-up and troubleshooting, and they can keep adding folders as needed. Phillips says there is really no limit to the number of QR codes, but for the first go-round, clients are keeping it to about eight or nine different codes for each season of field operation, perhaps for specific machines, as well as general administration files.

“Every time a farm has a salesperson, technician or knowledgeable neighbour on-site or on the phone to fix a common issue, they can quickly create a video or document and add it to the associated QR code,” says Phillips. “In essence, you are able to create an ever-growing, personalized, support library.”

Phillips, whose company has a focus on thought leadership, says he is not looking to make money from the QR code idea and Producers Edge doesn’t provide services to create and troubleshoot QR codes for producers.

However, for some free instruction on creating QR codes, visit the Producers Edge website at www.producersedge.ca, click on the “Blog” button and then click the “Using QR Codes on the Farm” button for a link on how to create QR codes. That’s free information from Producers Edge.

Both Cavers and Van Staveren are familiar with computers to some extent but neither one considers themselves a serious techie. However, with a minimal amount of technical help, they say they’ve been able to figure out how to create QR codes and add information folders as needed.

The farmers say it takes a bit of time initially to get information gathered and the QR codes created, but other than time the process is free. Codes created this winter, for example, may help improve efficiency in the field during the coming growing season.

The only money invested is a few dollars for label paper or, if desired, the cost of having waterproof QR codes printed. They say the code labels should be applied where they are accessible and, preferably, away from direct sun and out of the elements to add to their longevity (although it is easy enough to print new codes).