Colin Rosengren and Kelly Baillargeon farm on almost opposite ends of Saskatchewan, yet they have the same thinking when it comes to what they expect from precision farming and variable-rate technology (VRT).

Rosengren owns Rosengren Farms along with family members at Midale, in southeast Saskatchewan, while about 650 kilometres to the northwest, Baillargeon owns Bailla Farms along with his dad, Guy, and brother, Oneil, and family members at Edam, which is northwest of North Battleford.

Both farms, cropping several thousand acres of grains, pulses and oilseeds, began working several years ago with Cory Willness of CropPro Consulting and Croptimistic Technology using SWAT Maps-branded technology to help guide their variable-rate applications of crop inputs.

Read Also

Cereal lodging isn’t just a nitrogen problem

Lack of copper in the soil can also lead wheat and other cereal crops to lodge during wet seasons on the Canadian Prairies.

“There are variable-rate services that can produce a map with various production zones based on satellite imagery,” says Rosengren. “So, you can see the variation, but you don’t know why. The vegetation index might show there are two low-producing patches in a field, for example, but there’s no real explanation. The fact is the differences are for totally different reasons. One patch is a gravelly hilltop while the other is a low-lying area of salinity. What I liked about the SWAT Maps process is it tells you why there is production variability, which means you may be able to correct it.”

Baillargeon says the field-mapping process followed by soil testing and ground truthing gives him much more confidence in variable-rate prescriptions for crop inputs being applied.

“The amount of information you learn about your soil is incredible,” says Baillargeon. “As you travel over the various production zones in your fields, you can tell the prescription recognizes changes in the soil. By incorporating soil test information into the variable-rate prescription, I know, for example, this area of the field has low pH, so then I can correct that with a variable-rate application of lime (on his farm he uses wood ash). Or, in another area, maybe it is a sulphur issue. Using elemental sulphur, I can vary the rate of sulphur as needed and, hopefully, correct the imbalance. And if it is a saline area, I really limit the inputs.”

Both farmers say they found the SWAT-mapping process both thorough and accurate.

- Read more: Crop pictures worth a few thousand footsteps

What is SWAT all about?

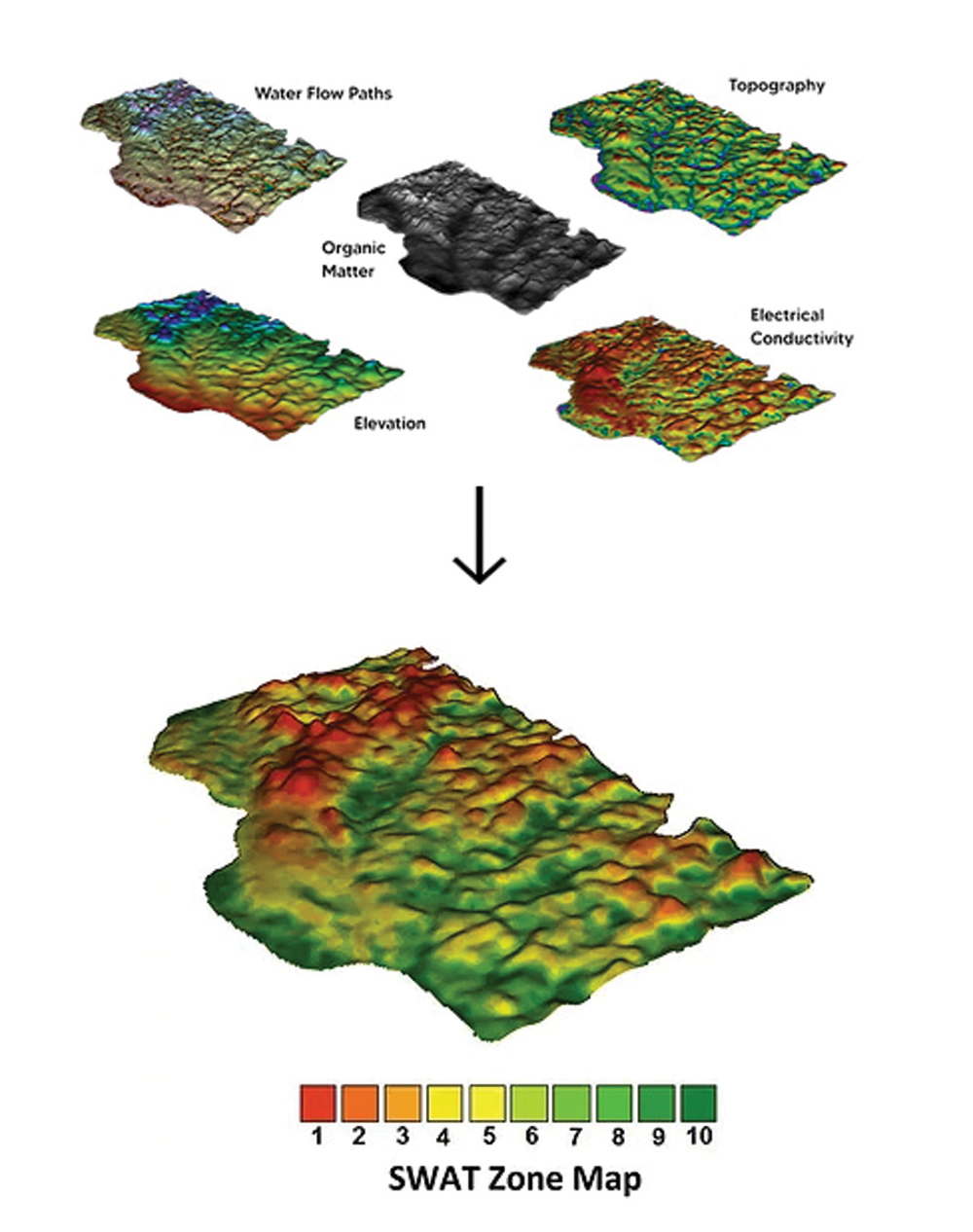

What are SWAT Maps? First, SWAT is the acronym for soil, water and topography. Those are the key pieces of field information layered together to form the foundation of SWAT Maps.

Willness started out about a dozen years ago using soil-sensing Veris technology, later switching to another patented soil-sensing system known as the SWAT Box — it involves an autonomous soil electrical conductivity- and elevation-mapping system.

Fields are scanned with the SWAT Box sensor, collecting information including topography, organic matter, elevation, electrical conductivity and water flow paths. With that data, map developers then create the zone maps of each field. The next step is to carry out soil sampling and testing and ground truthing across the various production zones, which is added to the SWAT Maps database. The final step is to analyze all of that information, develop a fertility plan and variable-rate prescriptions.

Willness and his team at CropPro Consulting based at Naicam, Sask., began developing the SWAT Maps process in 2008. Then in 2018, Willness and co-founder, Derek Massey, started Croptimistic Technology, an ag-tech company that provides the SWAT Maps ecosystem of hardware and software to service providers, such as other crop consultants and farmers across Canada, as well as the United States, South Africa and Australia.

“The key focus of the SWAT Maps process is identifying soil types and characteristics on each field in each production zone and helping farmers understand why there is production variability,” says Wes Anderson, vice-president of agronomy with Croptimistic Technology. “There are many factors that can affect yield and many of them can be temporal, such as seasonal moisture or hail or a one-year event such as herbicide drift.

“But then there are more stable soil and water properties that are consistent,” he says. “A hillside or knoll is always going to be the driest part of the field, while a low depression in a field will always be the wettest. The degree of dryness or moisture might change in relative terms, but those two sites won’t change. Similarly, production in a saline area of a field is always going to be salt limited.”

The layered information collected by the SWAT Box sensor identifies the various production variabilities and then ground truthing puts some flesh on the bones. Along with soil testing of the various production zones, ground truthing also involves collecting information such as soil depth, soil texture, stubble colour, and yield and crop quality information — all information which further explains production variability.

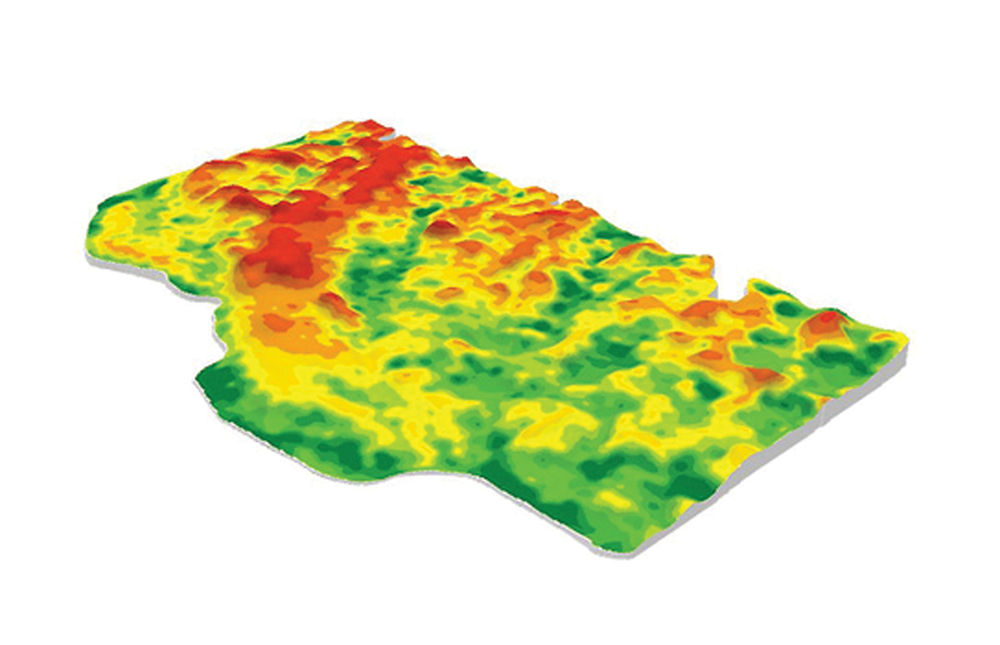

The SWAT-mapping process always identifies 10 production zones in each field. The details for each zone may vary, but Zone 1 will always be the driest part of the field while Zone 10 will always be the wettest.

Zones 1 and 2 are usually characterized as eroded knolls and hills and sandy and dry. Zones 3 and 4 are upper slopes and water-shedding areas. Zones 5 and 6 are mid-slopes, flat and average areas. Zones 7 and 8 are the toe slopes and lower flats and Zones 9 and 10 are water-collecting depressions and areas of high-clay content, peat and often salinity.

Based on farm- and field-specific data, a fertility plan and variable-rate prescription are developed.

“One of our service providers said it was more accurate to call it the optimum rate rather than variable rate,” says Anderson. “Based on all of the information we have on soil type and quality and water patterns for each field and production zones, the objective is to apply inputs where they will do the most good. It doesn’t necessarily mean reducing inputs, but a redistribution of inputs optimizing the production ability of each zone.”

Back to our farmers. How has variable-rate technology worked for Baillargeon and Rosengren?

The Bailla Farms experience

Baillargeon uses variable-rate prescriptions developed through the SWAT Maps process for both fertilizer and seeding operations.

He has two seeding systems — a 65-foot-wide Bourgault drill with an 800-bushel tank that has five compartments and a 70-foot Seed Hawk air drill with a 980-bushel tank with four compartments. All fields have been mapped showing 10 different production zones on each field. And the prescription has been written so the drills will apply different rates of fertilizer and seed as they pass over each zone.

The Seed Hawk drill offers more variable-rate flexibility than the Bourgault drill. The Bourgault can only vary input rates across its full 65-foot width, while the Seed Hawk has sectional controls and can vary the application rate every 10 feet across the 70-foot width of that drill.

In a one-pass seeding operation, crop fertility includes a blend of phosphorus and potash together. That blend is on one meter and applied at a variable rate. Nitrogen has a separate compartment and metering system and is applied at a variable rate, while the seed on another metering system is also applied at a variable rate depending on the production capability of each zone.

Baillargeon is now using elemental sulphur applied at a variable rate with a broadcast applicator. He aims to do about one-third of the farm each year. “I broadcast apply the elemental sulphur to ensure a steady supply of sulphur throughout the growing season on all of our crops,” he says. “I don’t like applying ammonium sulphate through our air drill as it can cause a lot of problems plugging hoses, especially during springs with high- humidity conditions.”

With soil testing and different production zones, Baillargeon is also able to identify those areas with low soil pH and then apply lime (or in his case wood ash) at a variable rate to try and improve productivity in those areas.

He says the variable-rate prescriptions don’t result in reduced amounts of fertilizer. “In fact, I don’t do it to save money, but what I am seeing is better, or more uniform, production over the whole farm.

“We are trying to increase overall production of the farm by managing parts of the field differently,” he says. “(We’re) going for higher yields in the areas of the field that are able to produce more and not overapplying nutrients in areas of the field that don’t have as much yield potential.”

Following a dry growing season like 2021, with only about 30 per cent of normal rainfall, soil testing is showing the amount of residual nitrogen varies considerably over the different production zones. But with crazy fertilizer prices and variable-rate technology, he can apply fertility as needed without overapplying.

Looking ahead, Baillargeon says he may use variable-rate technology to apply micronutrients as needed. And in growing seasons with increased disease risk, he will try variable-rate fungicide application.

The Rosengren farm experience

Rosengren has embraced variable-rate technology for several years, and for his grain, oilseed and pulse crop operation he has added variables to the variables.

With all fields mapped and 10 production zones per field, he develops both seeding and fertilizer variable-rate prescriptions for those inputs. Depending on the year, he grows between eight and 10 different crops.

But then to add another layer of complexity to seed and fertility planning, he seeds about half of the farm to an intercrop blend that includes peas, canola and lentils — all three crops are seeded at the same time, with variable seeding and fertility rates in different production zones in each field. That’s one of his favoured intercrop combinations but he also tries other mixes such as canola and soybeans, flax seeded with chickpeas and, last year, even corn and flax.

It all gets accomplished with a John Deere 1870 Conserva Pak drill that has two carts — one tow between and the other tow behind — each with three compartments. He also uses prescription-creating software supplied by CropPro Consulting.

“The first year, we tried SWAT mapping on just a couple of fields,” says Rosengren. “It made sense in theory, but we wanted to see if it actually delivered, and it did. Once the field is mapped and the prescription made, and you start seeding over the field, it completely made sense. The ground truthing that goes along with the SWAT Maps is exceptional.”

From those first couple of fields, he immediately had the rest of the farm scanned and ground truthed and now uses the SWAT Maps software to write his own prescriptions for each field and crop.

He finds it very user friendly and a very flexible process, making it possible to change prescriptions on the fly. “I can be seeding in one field and if it looks like moisture conditions have changed, for example, I can open the laptop and change the prescription before I get to the next field.”

The intercrop acres are an excellent example of matching the crop and inputs to the production capability of the soil. The peas, lentils and canola seed are in separate compartments in one air tank, while nitrogen, phosphorus and potash are in separate compartments in the second air cart.

Lentils are usually seeded a bit heavier in the drier zones, while peas are seeded heavier in the lower zones that usually have more moisture and canola is seeded throughout. It is a seemingly complex prescription with seeding rates and fertility rates being varied for each crop over the different production zones.

“If it appears moisture has changed at seeding, we can adjust the seeding rates and plant populations as the season goes,” he says.

Rosengren says variable-rate technology along with a good understanding of soil capabilities made intercropping a success story. “Once we figured out how to optimize inputs with this combination of crops, it definitely became a no-brainer,” he says. “I won’t grow these crops any other way.”

Rosengren says variable-rate inputs also help produce a malt barley crop with more consistent quality. “Depending on the production zone, we can push yields a bit harder and still keep protein levels down,” he says. “We can vary plant populations along with fertility and, if you do it right, it helps to even out crop maturity, keep protein levels within range and produce good-quality malt barley.”

He says while he doesn’t use many fungicides, he does see where variable-rate application would be beneficial with those products as well.