John Deere Air Seeder main.jpg

John Deere adds a 76-foot model to its 1870 air drill lineup and a new 850 bushel cart.

Photo: John Deere

Cart.JPG

The C850 drill has three main product tanks and a 50 bushel small product tank on mounted on load cells.

Photo: Scott Garvey

openers.JPG

Packing and trip pressure on the openers can be set from the tractor cab.

Photo: Scott Garvey

tank top.jpg

The C850 cart comes with a wiring harness that allows for the installation of in-tank cameras to monitor product levels.

Photo: Scott Garvey

JD-conveyor

The conveyors on Deere carts are now mounted on arms with five pivot points that allow for more manoeuvrability and easier loading of all tanks from one delivery location under a truck.

Photo: Scott Garvey

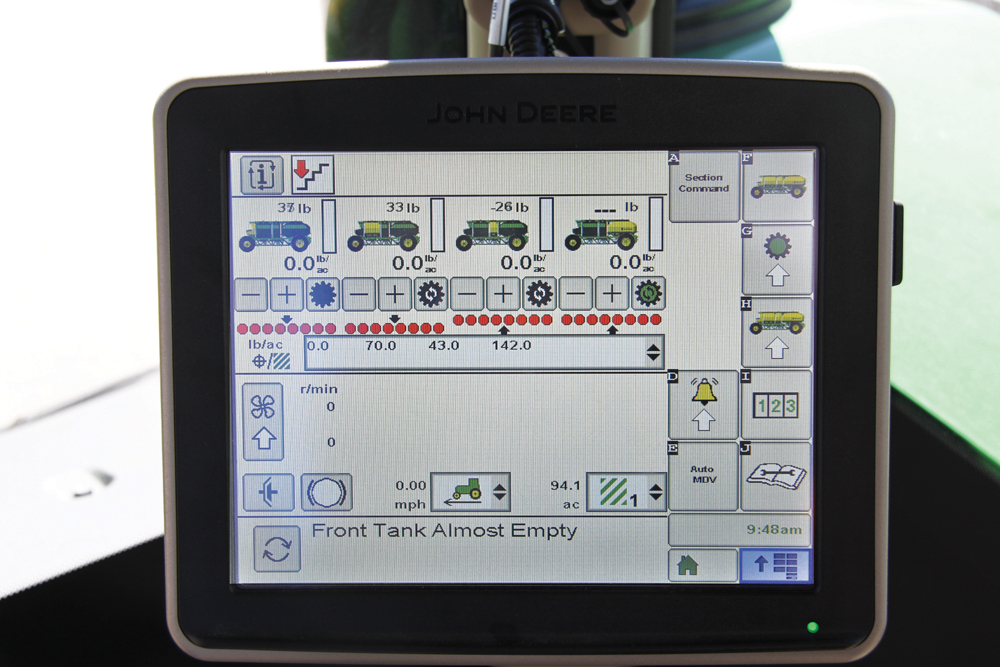

monitor.JPG

Load cell information on the C850 cart allows for seeding calibration rate adjustments right from the monitor in the tractor cab.

Photo: Scott Garvey

This year John Deere unveiled a wider air drill and all-new air cart at Canada’s Farm Progress Show in Regina.

The new addition to John Deere’s 1870 line of air drill toolbars stretches the maximum available working width to 76 feet, joining the existing 40- and 56-foot versions. The 76 footer is a five-section design with 12-inch row spacings. This wider toolbar gets more ground clearance and 56 inches of free space between each rank of openers. All the 1870 drills use a floating hitch and have 25 degrees of flex on the wings.

Read Also

John Deere introduces updated tech for its combine line

The 2027 model year will see the debut of several new features for John Deere’s line of combines, particularly the X9.

The drills can be mated to the brand’s updated 1910 Series 550 bushel tow-behind or 430 bushel tow-between or tow-behind air carts. The 1910s are now available with the new AirPower 2 dual fan option that can deliver up to 550 pounds of total product per acre by using two independently controlled fans.

But the all-new 850 bushel C850 air cart bumps up capacity even more.

“If there are three things that set this (cart) apart from the competition, it’s around accuracy, productivity and technology integration, said Tyson Harris, product specialist with John Deere, at Canada’s Farm Progress Show (CFPS) in June.

The C850 also uses the dual fan AirPower 2 system. “If you want to see rates higher than 550 lbs.per acre, added Harris, just slow it down from 5.5 (m.p.h.) to 5 or 4.8 and you can see rates as high as 600 and even upwards of 700 lbs. of product through it.”

The C850 has 260, 130 and 410 bushel main tanks along with a 50 bushel small-product tank at the front. They ride on load cells, which enables the operator to use the new active calibration feature and fine tune metering rates right from the tractor cab.

The C850 cart also gets disc brakes on the rear axle to help with stability both in the field and during road transport.

The 76 foot 1870 drill comes with Deere’s TruSet depth and pressure control system. “With the all new TruSet, it gives you in-cab adjustability of depth and pressure,” said Cody Wilkinson, Deere’s product rep. for the 1870 drill during CFPS. “Before you had shims and donuts that you’d have to adjust. All that has gone away now and you can do all that from inside the cab.”

The 1870 drills can band fertilizer up to six inches deep, and the seed tubes can be adjusted in ¼-inch increments. A cam lever on each opener makes it easier to adjust seeding depth.

“Another nice new feature on the 1870 is Relative Flow blockage sensing,” adds Wilkinson. “Previously, we had blockage monitoring, but we’ve taken that a step forward with being able to compare flow from tower to tower. We have secondary lines being compared to one another. If, for example, you had some fertilizer that was gummed up and you weren’t getting the flow you wanted, our system is sensitive enough to detect that show it in the cab to the operator.”

For road transport, the 76 foot 1870 folds up completely in two minutes and the retractable openers narrow the folded width to 22.5 feet. A “bump up” and “duck down” feature allows operators to increase ground clearance by four inches to clear obstacles.

To make headland turns quicker, the toolbars reach full lift in the field in 7.5 seconds. And the use of more greaseless bushings and long-life components cuts service time.