Field_cmyk.jpg

A TD6 pulls a plow through clay soil.

Photo: Supplied

TD line.jpg

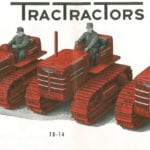

In 1940 a complete innovative new line of crawlers was introduced as shown in this introductory literature from the day. Included were the T-6,T-9 and T-14 gas models, but the brand focused on the TD-6 through TD-18 diesels.

Photo: Supplied

The Thirty Five TracTracTor.jpg

IH experimented with tracked versions of the 10 to 20- and 15 to 30-wheel tractors in the late 1920s. In 1930 a T-15 was released but was not built in quantities until it was introduced as a Model T-20 in July of 1931. In 1932 a T-40 was added, but it was not unti 1936 when the first agricultural targeted track layer models, the T-30 and a companion diesel TD-35 were introduced.

Photo: Supplied

Tractor trains_gc.jpg

Tractor trains, or Swings as they were called, were made up of TD-6s. They were “lake swings” because of their lighter weight or TD-9s/TD-14s were used for overland treks. The TD-6s were open station to allow the drivers to jump off if a tractor went through the ice. The trains were completely self contained with a crew including a swing boss, a cook, a breakie, and drivers to operate 24 hours a day. When not driving they lived in the caboose which had a “breakaway” hitch and was designed to float if the rest of the train went down.

Photo: Supplied

The period after the First World War, I saw an explosion in farm tractor innovation. International Harvester engineers were aware of the work being done by Holt and others in the design of track laying tractors; and as a result they experimented with new versions of the eight to 16 wheel tractors, including one with tracks and another with four or six same size wheels, somewhat similar to present day skid steers. However, the need to bring out a serious competitor to the very successful Fordson took priority and resulted in the 10 to 20- and 15 to 30-wheel tractors and in 1924 the world’s first row crop tractor the Farmall Regular.

Read Also

John Deere introduces updated tech for its combine line

The 2027 model year will see the debut of several new features for John Deere’s line of combines, particularly the X9.

But the tracked concept was not forgotten, and in 1928 an experimental 10 to 20 track layer was developed. It was to be a T15 TracTracTor but only a limited pre-production number (50) were built before they were replaced by the T20 in 1930. The T20 was followed by a big 45 horsepower T40 in 1932. In the mid 1930s IH introduced diesel power with the TD35 crawler and WD40 wheel tractor. In 1939 a new and modern series of crawler tractors were introduced including the TD6, 9, 14 and 18 along with gas versions of the T6 and T9. A gas T14 was also available but few were sold and they were discontinued in 1946. This series was filled out in 1947 with the release of the 20-ton TD24.

The Second World War stopped the sale of farm crawlers but there was a great military demand. The U.S. Navy used IH tractors extensively, and after Pearl Harbor the Seebees (U.S. Navy Construction Branch) played a major part in reclaiming the Pacific islands. I had an uncle who operated a TD14 building advance air bases as the islands were captured. Apparently, the TD14 was the biggest crawler that could be carried by a Marine landing craft.

In Canada, the Commonwealth Air Training Program was established to train air crews from all corners of the British Commonwealth and required major airfield construction, including many places in Western Canada. After the war much of the equipment was sold, and some of the TD6s and 9s found their way to farms in the Red River Valley, where compaction caused by the weight and slippage of two-wheel drive tractors had come to be recognized as a major problem in the heavy clay gumbo. Most of our family farm was located on the shore of what had been Lake Agassiz so there wasn’t much gumbo but many of our neighbors to the west bought TD6s and TD9s to address compaction particularly in the spring. Service of these crawlers was a major part of the Dominion City IH dealer’s business.

Immediately after the war, under the provisions of the Marshall Plan, large quantities of equipment were sent to Europe for reconstruction. In Holland there was a depot to receive and assemble IH crawler tractors and a young Dutch mechanic named Herman Ballast was part of the crew. A bit later he and his family immigrated to Canada and he took a job with the local IH dealer. His diligence and work ethic (when Herman said he would be out in the morning he meant about 5:30) gained him a reputation and in a few years he bought the dealership, which he ran until retirement.

Another IH crawler story from Manitoba involved the Sigfusson family from Lundar, who developed a winter business hauling frozen fish from northern lakes, This grew into a large company who used IH crawlers exclusively to haul freight over 3,500 miles of winter roads in northern Manitoba, Saskatchewan and western Ontario. These roads were all built and maintained by Sigfusson Transportation with up to 400 employees. In the early days of the “cat trains” there was no communication and they were truly on their own their own to cope with weather, bad ice and maintenance.

The TD6s and 9s were all “open station” to allow operators a chance to jump clear before the tractor sank. Repairs were made by skill and ingenuity. One example, I recall, was when they lost a bearing on the transmission of a TD9, which was pulling a string of freight sleighs. They carved a bearing out of seasoned oak, boiled it in oil overnight, installed it the next morning and drove 200 miles to base.

Eventually the noisy, hot, dusty farm crawler business largely dried up. There was, however, a market developing for smaller, a lighter crawler for specialty applications. This resulted in many companies offering what are now called compact crawlers. International Harvester was no exception but decided to go one step further and build the line of small crawlers in Canada. I’ll share that story with you in a future issue of Grainews.