Just as technology gives producers a tool to improve on-farm efficiency and reduce operating costs on combines, tractors, and drills, brands have been taking that technology and applying it to tillage implements for the same reason. Case IH recently introduced its AFS Soil Command, which brings digital tech to its red line of tillage implements.

Case IH tillage tools equipped with that AFS Soil Command provide easy implement set up, and the system also allows for quick in-field adjustments, allowing them to adapt to changing conditions across a field. That’ something growers running the previous generation of “dumb iron” couldn’t even think of doing. Making adjustments could be a painstaking process on old tillage implements.

Read Also

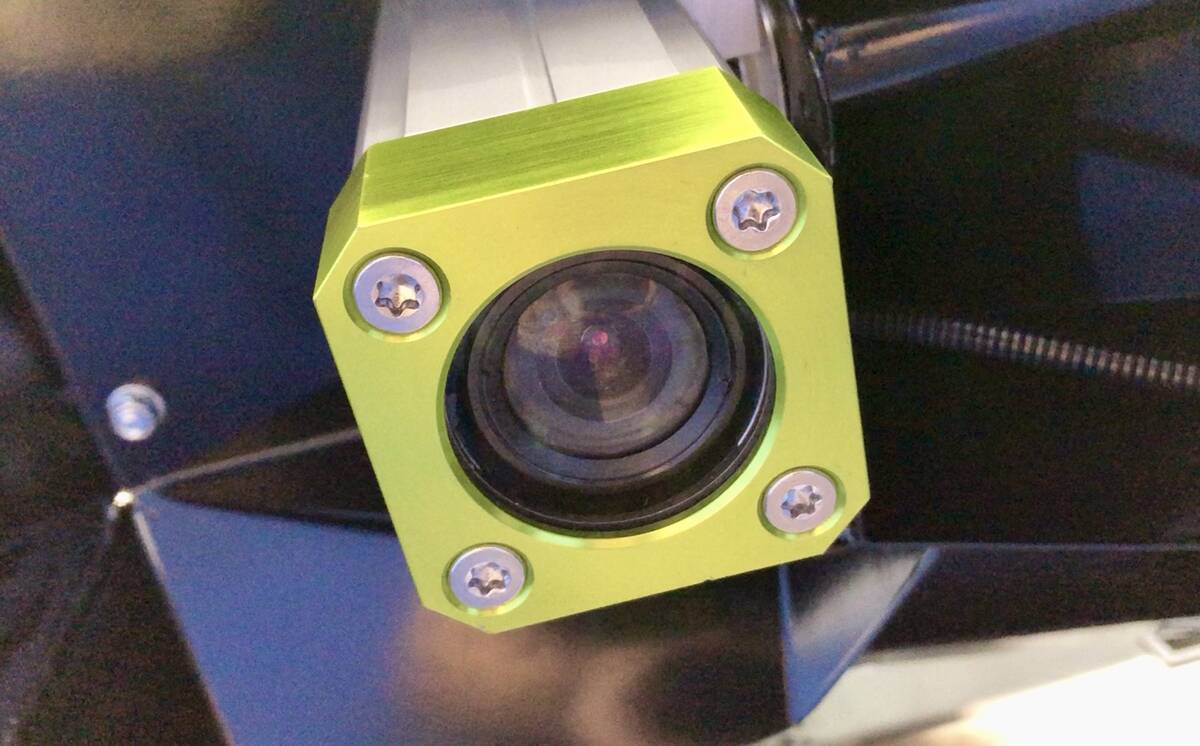

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

Now with the brand’s AFS Soil Command, changes happen with just the press of a button in the cab.

“AFS Soil Command, it’s agronomic control technology that helps customers optimize their in-field settings,” said David Brennan, Case IH territory sales manager, during an in-field demonstration in Arizona in January. “Those changes can be made in the cab. A producer can go in ahead of time and save settings, so he doesn’t have to worry about any changes being made by (an inexperienced) operator. We can adjust for soil conditions: lightening pressure, changing the fore-aft levelling, changing machine depth. It’s one button for the operator to press to do that.”

And also, unlike the previous generation of tillage implements, today’s machines are much more complex; and they usually have multiple types of ground engaging mechanisms on one frame, all of which have a different agronomic function to perform. Adjust one of them alone and that could throw all the others off. But AFS Soil Command takes that into account by ensuring changes don’t affect the machine’s overall performance.

“Co-ordinated machine control is the unique piece; it makes all the necessary changes to settings together,” added Brennan. “As we go deeper, we need to make changes so we don’t get the machine skewed.”

An example of that is the ability to change the down pressure on the rear rolling baskets (or crumblers as Case IH prefers to call them). If that pressure isn’t set just right for field conditions, they can plug or cause more trouble than they cure.

“Now we have the ability to hydraulically control down pressure,” Brennan said. “If it’s late in the season and wet, maybe I just want it to float. It’s just the weight of the assembly along for the ride, but it still gives me some soil forming. In really wet conditions I can get them up in the air and out of the way.”