Two “right to repair” bills — Bill C-244 and Bill C-294 — that passed in Parliament and got royal assent last month will give Canadian farmers more latitude to fix electronics on their own equipment.

Although the right to repair has been high on growers’ wish lists for several years now, it doesn’t mean all individual farmers will be willing to invest time in learning about the guts of electronic systems. But who else is specialized enough to fix them?

There are a few repair shops dotting the Prairies which specialize in ag electronics, including older parts that may no longer carry manufacturer support. ChDp Ventures at Muenster, Sask. is one such company.

Read Also

John Deere introduces updated tech for its combine line

The 2027 model year will see the debut of several new features for John Deere’s line of combines, particularly the X9.

“We repair anything to do with ag electronics and some industrial electronics,” ChDp owner Christian Herrnbock wrote in an email. “So air drill monitors, GPS systems, receivers, sensing equipment, (et cetera).

Herrnbock is able to “reverse-engineer” the circuit boards of electronic devices to find a fix. Defined at its simplest, reverse engineering means studying a program or system structure and then rebuilding it.

“Reverse-engineering circuit boards isn’t that complicated. Repairs, oftentimes, don’t even need reverse-engineering. Symptoms often tell you what the issue is,” he wrote.

Speaking prior to the right-to-repair bills’ passage, Herrnbock wishes he had more access to detailed repair instructions. A major grievance in the right-to-repair movement has been owners’ inability to claim instruction manuals held by the manufacturers.

Past that, “sometimes having access to more schematics and documentation would help speed up the repair process… With the complexities of newer systems, even dealerships don’t have the tools to properly diagnose and repair.”

Arable Automation, run by Steven Herbert in the central Alberta village of Edberg, is a repair franchise of ChDp Ventures. Herbert — who serves the entire province — specializes in the hardware side of farm electronics.

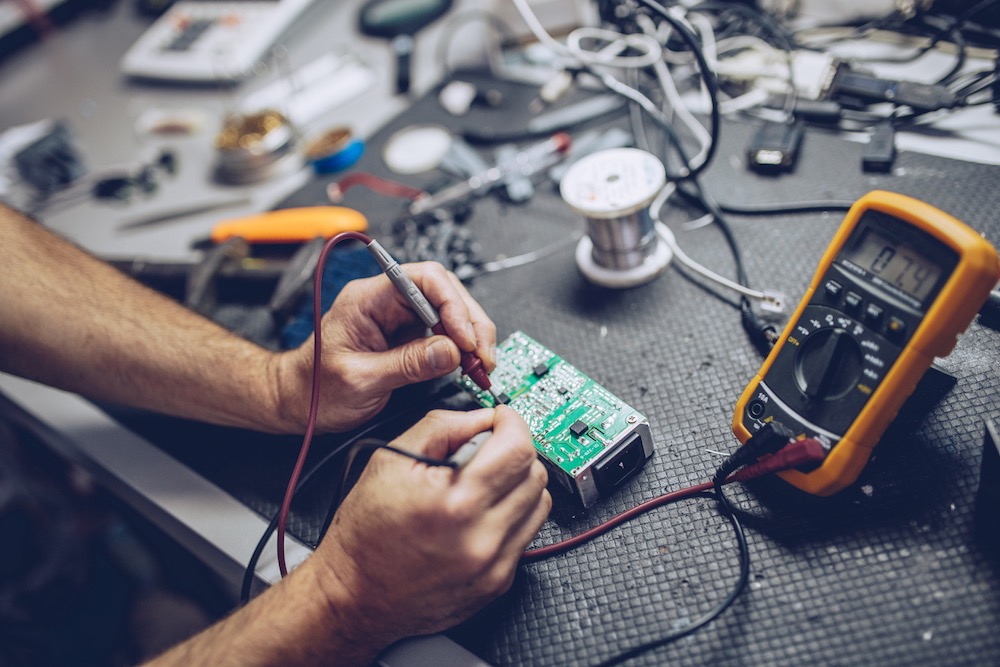

Some hardware fixes — replacing a touchscreen, for example — can be fairly simple, he says. It gets more complicated if the problem goes further into the guts of the unit, such as a circuit board.

“It’s (using) a lot of multimeters, scopes and things like that for doing hardware diagnostics, having soldering tools, reflow tools for working on circuit boards,” he says.

Customers often come to Herbert because they don’t want to invest their limited time into learning how to fix these units themselves, he says.

The rush to obsolescence

A farmer himself, Herrnbock — who describes his background as “tinkerer” — is privy to some of the goals of the major equipment and parts manufacturers, including “phased obsolescence.”

“Manufacturers want to have phased obsolescence to encourage new sales,” he wrote.

“I’m not one to want to waste or litter. It seemed like a total waste to throw out a controller or a monitor because of a $50 piece being broken.”

Herbert, who works on his family’s small mixed farm, said the goals of some manufacturers today go beyond planned obsolescence into what he calls “forced obsolescence.”

“If a company can just decide one day, ‘OK, we’re disabling this service, this product, and we’re going to force the consumer to upgrade to the next generation or a new generation simply because our revenue is not high enough,’ well, then that isn’t really a very friendly behaviour towards small farmers.”

It’s those small farmers who suffer the most from such company policies, Herbert says.

“Sure, the corporate operations that are doing 5,000, 10,000, 50,000 acres, that doesn’t really matter much to them because they’re on the current generation anyway. But if there’s someone still running John Deere iTC (receiver) they’re probably running it for a reason — they can’t afford to upgrade.”

Right to repair

With the two “right to repair” bills receiving royal assent, farmers and independent repair techs should literally have more tools in their toolbox to repair their electronic equipment.

Bill C-244 amends the Copyright Act to allow farmers and others to bypass digital locks and access diagnostic software needed to repair machinery.

Bill C-294 amends the same act, to allow for increased interoperability of different technologies, including parts and computer programs, without violating copyright laws.

Speaking prior to the announcement, Herbert said he often finds himself digitally locked out of relatively simple hardware repairs, which he finds frustrating because he’s not doing anything software-related.

READ MORE: Could ‘right to repair’ become a cybersecurity problem?

“My understanding of how it works in the John Deere case is, say something fails: they replace the part, then they have to have their digital wrench for their software to connect to the machine and reset the error to allow the machine to function again,” he says.

“And that seems to me that that’s unreasonable and unfair to require that specific step to reset the error. And that requires John Deere software, which is encrypted.”

Herbert believes if someone buys a product, it should be owned outright and owners should have freedom to do anything they wish with it. Any objections the manufacturer might have end at transaction.

That said, he understands the intellectual property status granted software and emphasized he’s not interested in that degree of access. What he doesn’t understand is why these companies would place lockouts to prevent buyers from making hardware fixes.

“I’m not asking for these companies to provide their complete software package to farmers, but to specifically software-lock a repair that is a physical hardware repair, that’s crossing a line in my opinion.”

Because of his focus on hardware, Herbert isn’t worried about litigation from equipment manufacturers.

“It’s the same as your oven. If your oven display goes out or something, you just pull out the main boards and you find if there’s (a) short on it that can be repaired, or if it burnt a hole through the circuit board, then just replace the board entirely.”

CORRECTION, Jan. 10, 2025: Article adjusted to correct the name of Arable Automation’s home town. We regret the error.