Bring up tile drainage in a conversation, and you might get some very different responses.

Some, particularly farmers who have used it to boost production and manage water or salinity on perennially challenging fields, will sing the practice’s praises. Others worry about downstream regional water management or waterway nutrient loading in heavily tiled areas.

The potential cropping benefits of tile drainage have sparked creative methods and research to overcome some of the environmental shortfalls, such as recycling tile-sourced water and reserving it for a farm’s use during dry times.

Read Also

When post-emergence soybean rolling works, and when it doesn’t

New research from the University of Manitoba outlines when post-emergence soybean rolling can be done safely and when plant damage and yield risk rise.

Agriculture has been playing with some of those concepts for years, such as bioreactors and constructed wetlands to act as natural filters and help address nutrient leaching from tiled fields into wider waterways.

Tile discharge drains water from a wide area to a single point, noted Matthew Reid, an assistant professor and researcher of civil and environmental engineering at Cornell University, during the recent Pan-American Light Sources for Agriculture Conference in Saskatoon, Sask. That potentially opens the door to “build something to try to mitigate some of those nutrient losses,” he said, such as the aforementioned bioreactors.

“The drainage water, instead of discharging directly into streams, can be diverted through basically a trench, which is filled with wood chips … and the purpose is to provide a carbon source for biofilm that can then denitrify the nitrate,” Reid said, noting other agricultural residues can be substituted for the wood chips.

That last point dovetails with his work on improving bioreactors. He’s trying to get a better idea of how wood decomposes and how that affects the wood chips’ ability to filter nitrogen.

Wood is a relatively poor carbon source. One of its biological components, lignin, creates a layer of cellulose that protects the wood from microbial accessibility in low oxygen conditions and slows decomposition.

Lighting up microscopic insight

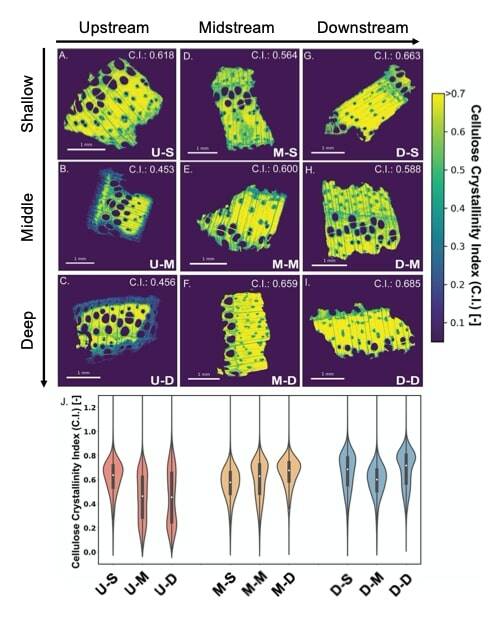

Using eight-year-old wood from a bioreactor at a Cornell experimental farm, Reid and his team collected nine samples from close to the discharge, midstream and downstream at three different depths. The samples were then taken to the lab and incubated with nitrate.

“We found that there was a significant amount of spatial variability in how effectively wood chips collected from different parts of the reactor were able to remove nitrate,” he reported.

Analysis found that a low carbon-to-nitrogen ratio was linked to more degraded wood, higher surface protein concentrations, and thicker biofilm density. This, in turn, caused a greater release of dissolved organic carbon and quicker nitrate removal. In short, more degradation leads to more denitrification.

“At first that might seem a little bit counterintuitive,” Reid said, “but what this is in fact saying, is that we need the wood to be decomposing and releasing carbon if it’s going to be an effective support and an effective carbon source for the denitrifiers.”

To get a micro-scale, detailed look at what was happening during the degradation process, and to gather ideas on how to influence it, Reid turned to the facilities at the National Synchrotron Light Source II (NSLS-II) and the Cornell High Energy Synchrotron Source (CHESS). Using these powerful X-ray beams, he conducted micro-tomography and scattering experiments to visualize crystalline cellulose in the decomposing wood and track how its structure changed as it broke down.

At this scale, the team mapped cellulose depletion in their nine samples, with yellow indicating intact wood and blue showing areas of degradation.

“When we specifically look at the upstream parts of the reactor, (and) in the deeper parts of the reactor, we see the surface of the wood as characterized by these bluer colors is telling us that … the cellulose is more depleted,” Reid said.

For the other parts of the reactor (midstream and downstream at the shallow, middle and deep depths), the wood was mostly yellow, indicating it was mostly still intact despite being environmentally aged for eight years.

Reid suggested two reasons for this. The first is that the upstream parts of the reactor are exposed to higher levels of oxygen, which is needed in high quantities for the degradation of lignin. And the second is that concentrations of iron and manganese are higher in the deep, upstream parts of the reactor. There’s a theory that the two minerals could play a role in wood degradation.

His team noted iron accumulating on the surface of wood chips and measured the minerals inside using the synchrotron X-ray.

“We were able to see that in the interior of the wood, we see reduced forms of iron and manganese. (And) by the surface, there’s more oxidized iron and manganese,” he said, adding that proves the minerals’ oxidation reaction effects degradation and release of carbon.

Bioreactors need air time?

Under normal conditions, bioreactors are permanently flooded. However, the permanent flooding limits opportunity for oxidation and, according to Reid’s research, the needed wood degradation.

His suggestion was that the structures might need to be periodically drained.

“Expose the wood to oxygen, and then when it’s reflooded, we can have enhanced labile carbon release, which will then enhance denitrification rates,” he said.

His lab tested the idea and saw denitrification rates rise after reflooding. Reid is still investigating how to optimize the approach and strike the right balance for field conditions.