Nearly every modern combine has a loss monitor in it. But what exactly are those monitors telling you? What, if anything, can you understand from the blinking lights on those graphics?

During a presentation to growers in Brandon in March, Joel McDonald, an engineer at the Prairie Agricultural Machinery Institute, said PAMI undertook a study a couple of years ago to see if it could translate the symbols into more relatable data, such as bushels-per-acre loss.

“In 2017 we did a project in Saskatchewan looking at grain loss monitors and ‘Can we use the signal from a grain loss monitor to indicate bushels per acre loss instead of a unit less bar graph or a colourful funnel?” he said. “Why not tell it to farmers in bushels per acre? You’d still have to calibrate it. But if instead of flashing red it was flashing five bushels per acre, maybe that would be a more useful bit of information.

Read Also

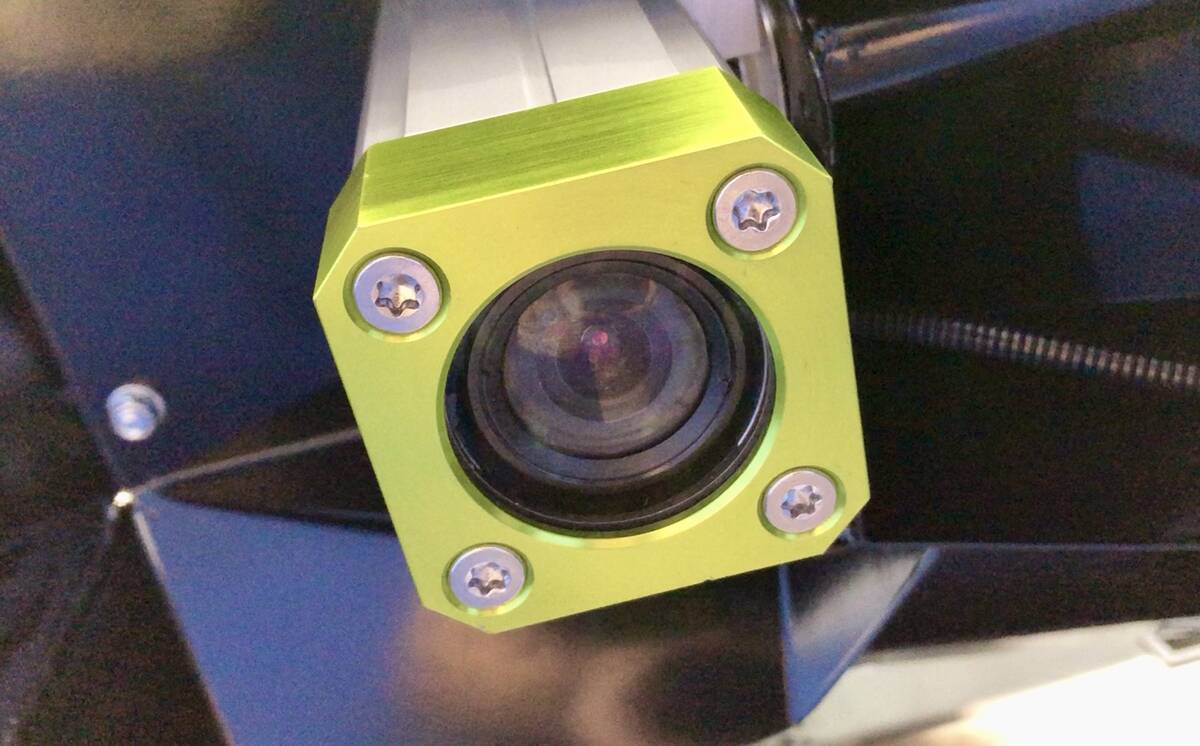

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

“We did that. We recorded the readings on the monitor and the actual losses out the back of the combine, and then we measured the raw signal off the loss sensor. The findings from that showed that when losses were increasing, the monitor showed an increase, but it wasn’t proportional to the actual loss. Toward the higher end of that loss, once we started getting up into the two to three bushels per acre, the monitor didn’t have the resolution to show the loss was in fact five times what it was at a more reasonable speed. That was in canola, peas and wheat.”

Without relating monitor readings to actual data from catch pan analysis, the indicator lights aren’t telling you much.

Currently, there is nothing like a Nebraska Tractor Test report for combines that provides any hard and fast performance data, so in-field verification remains the only way to determine how they’re doing.

“Find a way to make it easy,” said McDonald. “Find a way that you’ll do it regularly, because it’s important. Catch some residue. It can be a garbage can lid; it could be a Rubbermaid tote lid, virtually anything you could toss under there.”

Once you’ve taken those samples, measure them to determine loss per acre.

“Then you have to quantify the seeds you’ve got for the effective catch area,” he said. “You can measure those by weight, volume or seed count. It doesn’t matter which method you use. What really matters is that you’re doing it.”

Once you’ve calculated the losses a couple of times, making rough notes on the catch pan can speed up the process and give you approximate loss amounts on a bushels-per-acre basis, which should be adequate

to help you determine what, if any, adjustments are required.

“Take a Jiffy marker and write it on your loss pan,” he said. “Then you can take your (conversion) chart or app and throw it in the glove box. We’re not looking for three digits of precision.”