An angle grinder is used to smoothen out the weld bead and make the bumper look like one seamless piece.

Photo: Scott Garvey

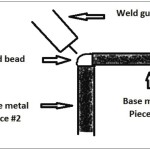

The proper fit up for welding an outside 90-degree joint allows the weld bead to fill the corner and ensures good penetration into both pieces of base metal. Note the proper angle of the MIG gun, allowing it to direct heat evenly into both pieces of base metal.

Photo:

Using a scribe to mark cut lines allows for transferring precise measurements and exactly positioning the torch guide.

Photo: Scott Garvey

A framing square was used as a guide for the plasma torch to ensure a perfectly straight edge.

Photo: Scott Garvey

The plasma cutter leaves a striated edge on the steel similar to that of an acetylene torch. It requires some dressing with a grinder to create a finished face.

Photo: Scott Garvey

Welding was spread out along the length of the joint to prevent concentrating heat into one area and warping the metal.

Photo: Scott Garvey

An angle grinder is used to smoothen out the weld bead and make the bumper look like one seamless piece.

Photo: Scott Garvey

Fitted into place with the original bent and broken part behind it, the replacement bumper looks exactly like the original once did. The only thing left to do is drill holes for the mounting bolts.

Photo: Scott Garvey

Here’s a tip. If you don’t take time to cut the steel properly, create good joint fitment and understand how to avoid the problems that applying a lot of heat to a piece of steel can create, the finished product will have a weak weld joint or won’t fit because it’s warped from heat distortion. That can turn love of burnin’ stick into extreme frustration and wasted effort.