Walking through the SeedMaster R&D shop, company president Norbert Beaujot stops beside a group of distribution towers that includes one of his company’s along with some competing models currently on the market. He explains the testing work company engineers have done on them to determine how well they distribute product to openers.

“The thing we found with everybody’s towers, they’re so unpredictable,” he said, as he walked up to one of the test stands and moved one of the seed tubes up and down. “If this hose happens to go up a little bit, it will get less seed going through it than the one beside it going down. So many of those things you just can’t control. It’s great that it’s nice and flexible, but it changes the metering characteristics in a big way.”

Read Also

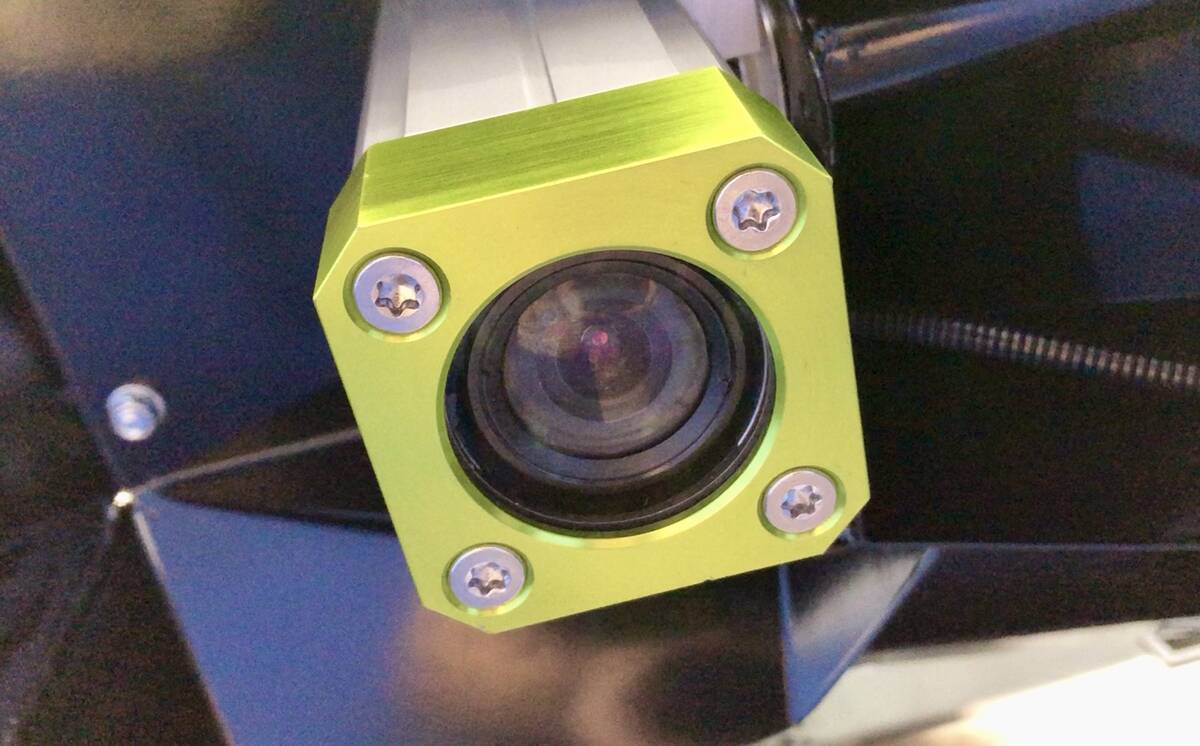

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

“We were holding the hoses higher or lower and tilting the manifolds 10 degrees and analyzing it,” he continued, explaining the various testing steps. “The standard manifold system can easily vary 25 to 30 per cent.”

Those tests identified problems Beaujot says are inherent in the distribution tower concept used by all brands. Put simply, there can be a lot of variation in how much seed goes into one opener run compared to others on the same tower. However, he notes the end result of understanding the amount of variation that occurs and knowing what factors influence it led to the creation of SeedMaster’s new “tuneable” distribution towers.

But because there are so many subtle changes that can cause big variations, adjustable towers are only useful if an operator knows in real time how the flow of product through them is dividing. Adopting the digital XeedSystem flow monitoring technology from Hungarian tech firm Digitroll provides that data to an operator, and paring those two features together made the tuneable towers a viable option the brand will offer on its 2017 model year drills.

The XeedSystem flow monitoring system gives an operator exact, real time data that can show if the division of product flow through a distribution tower is reasonably even or needs correction. If the level of variation is too high, operators can quickly adjust airflow through the individual towers to match conditions.

“For a number of years now SeedMaster has been seeking out the best product for a blockage detection system,” says Research Farm manager Own Kinch. “What we have now is not just a blockage detection system, but a flow monitoring system.”

“It (XeedSystem) actually has the ability to count individual granules to an extremely high level of accuracy,” he adds. “Ninety-eight to 99 per cent. That’s for any seed from something small in size like canola to something very large like a faba bean. What that has done is give us access to some very powerful information, real time, live inside the tractor cab.”

The company has actually gone so far as to manually check that XeedSystem really has that much accuracy, even on small-seed grains, Beaujot said.

In the tractor cab, operators can select from a couple of display options on the monitor. “You can have it display different views,” Kinch continues. “You can have it in a bar graph format that is updated second by second in real time. Or you can have it on a seed count feature.”

Based on that information, the tuneable distribution towers, which were developed in SeedMaster’s R&D shop, can be fine tuned using either of two separate adjustment features.

“It has a removable top and there are two methods of causing an interference to air flow to ultimately reduce that flow deviation to more acceptable numbers,” Kinch says. “There is a centre mass-flow adjustment. That’s particularly useful where you have multiple runs side by side that are either high or low. And then there are individual pin adjustments (for each run).

Making those changes can bring down the variation in row-to-row distribution to what the company considers a more acceptable level.

“We’ve taken the bulk metering system from a (standard) 25 per cent variance down to less than 10,” says Trent Meyer, the company’s sales and marketing director.