When it introduced its new 2015 product line at an event in Milwaukee, Wisconsin, in August, John Deere significantly beefed up its hay and forage implement offerings. Arguably the most notable additions to that segment were the two L Series balers that will be market ready for the upcoming season.

“This is one we’ve been waiting to come to the market with for quite a while,” says Jeremy Unruh, product line manager for hay and forage. “We’re excited about it. I think this is a big one for us.”

Read Also

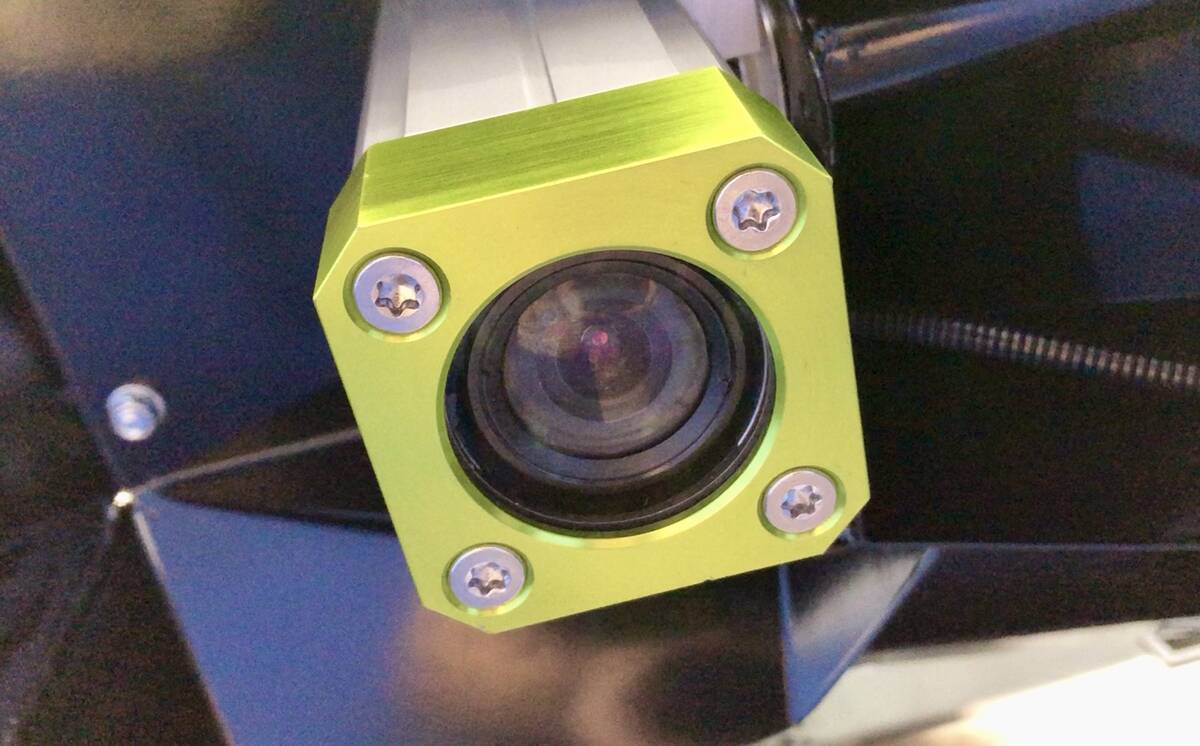

Yield EyeQ camera system measures harvest loss at header

Harvest equipment manufacturer Geringhoff won a silver Innovation Award at Agritechnica for its Yield EyeQ camera system, meant to help farmers measure grain loss at harvest.

The L330 and L340 will make 3×3 foot and 3×4 foot bales, respectively. In 2011, Deere purchased authorization to use European haying equipment manufacturer Kuhn’s basic baler design in the development of the L Series. And although the Kuhn baler formed the basis for Deere engineers to build on, extensive redesign and more than a little in-house engineering makes these uniquely John Deere.

“This is a John Deere designed and manufactured product,” Unruh continues. “We’ve actually started a new line at the factory. We have over 2,100 parts on this baler, and we’ve designed 85 per cent of them. We took that design (from Kuhn) and it helped us get started out of the gate. We changed 85 per cent of that baler, or maybe a little bit more, to make sure it fit our needs in the North American market. What we bought was a single-tie machine that was manufactured in Europe and what we are producing is a double-tie machine manufactured in Ottumwa, Iowa.”

The double-tie knotters reduce the number of misses compared to single-tie versions, say Deere’s product marketing reps. The knotters use a replaceable billhook and wiper plate, making repairs a little easier. The balers also use hydraulically-driven cleaning fans to keep debris out of the knotters.

“On this system if there is a problem with the knotter, you can take it apart without having to pull out the entire shaft,” says Louis Fernandez, senior marketing rep.

And to keep all the key components properly timed, the L Series models use direct drives rather than chains. “Our timed components are gear and shaft drive,” Fernandez adds. “Some of our competition uses chain drives. Over time chains will stretch, and we have a lot of moving parts in here that all need to be in correct time.”

Buyers have a choice of a standard feeder system or one that pre-cuts the crop feeding in, which research has shown helps improve feed utilization.

“They come in two configurations,” says Unruh. “The first is a standard rotor. The second configuration is a pre-cutter. A pre-cutter helps you size the material, which allows a cow, sheep or horse to better digest it. We call it theoretical cut (length), because it’s not going to be perfect, but we can get from six inches down to about an inch and a half.”

Although the L Series balers are designed to mate seamlessly with Deere’s own GreenStar monitor, they are ISOBus compatible, so they can be controlled by a virtual terminal from any tractor.

“If a customer has a different coloured tractor, using ISOBus, we utilize it that way as well, but we see optimization with a green-on-green solution,” Unruh adds.

And although the balers aren’t available with moisture sensors at the moment, Unruh says that feature is currently in development and will likely be an option in the future.

“Based on our test performance and field tests the factory has completed, our bale shape, our size and the ability to stack a truck or fill up a barn is going to be right on par or a little bit better than those (competing brands of balers) on the market today,” he continues. “We’re looking at getting these machines to our dealers in time for the 2015 hay season.”