When trying to enhance crop production with fertilizer, we first need to answer the following questions: What crop yields are possible and what fertility and moisture are required to get there?

Crops exhibit different water use efficiency in every part of the Prairies. Water use efficiency is also weather dependent and when combined with best management practices for fertilizers and desirable crop genetics it leads to maximum yields. The late Les Henry and I exerted significant effort to derive yield equations for the Prairies that are based on water-use efficiency. The “available growth water” for any crop is based on “available” soil water plus growing season (May, June, July) precipitation, plus irrigation, where applicable.

We can obtain information such as average values from Environment Canada or provincial data. We can also gather actual values from farmer precipitation records, Brown moisture probe and soil texture to convert moist soil depth to available water. Finally, we need to determine which fertility products work and which do not, and, of course, choose the former.

Read Also

Southern Alberta farms explore ultra-early seeding

Southern Alberta farmers putting research into practice, pushing ahead traditional seeding times by months for spring wheat and durum

Advanced nitrogen management

Nitrogen (N) fertilizer management is receiving considerable attention these days due to fluctuating prices of nitrogen fertilizers and crops and the realization that maximum yield does not always result in maximum profit. The amount that a producer spends on additional fertilizer to achieve maximum yield may not result in higher profit, or at times, a profit at all. It is important to remember that:

(crop price x yield inc.) – (N price x N rate) = Net Return

Hence the 4R (right source at the right rate, right place and right time) principle leads to selecting the right fertilizer product and using it at the right rate to achieve maximum economic return. The key is to manage N availability for plants by reducing losses, especially when there is a long period from application to crop demand. During this period, N is susceptible to loss as a result of primarily three loss pathways — volatilization, denitrification and leaching.

Enhanced efficiency fertilizers can play a role by offering protection against these loss mechanisms.

Enhanced efficiency fertilizer

Based on the definition provided by the Association of American Plant Food Control Officials (AAPFCO 2008), enhanced efficiency describes fertilizer products with characteristics that allow increased plant uptake and reduce the potential of nutrient losses to the environment, such as gaseous losses, leaching or runoff, as compared to an appropriate reference product. Urea has been our common reference product.

Why the interest in enhanced efficiency fertilizers now? Enhanced efficiency fertilizers are part of a good 4R nutrient stewardship plan. Relative research on 4R nutrient stewardship has shown that enhanced efficiency fertilizers optimize soil and nutrient management, improve crop yields, lower environmental losses without sacrificing yield potential and, based on their definition, grow more on less land.

However, producers rarely have the means nor the luxury of time to strictly adhere to these principles. Therefore, it appears that one of the main reasons that producers move to using enhanced efficiency fertilizers is for operational efficiencies versus agronomic efficiencies, due to increasing farm size. Based on Statistics Canada data, the average size of farms has doubled in the last 50 years, whereas the number of farms decreased by the same proportion.

Let us examine some examples starting with broadcasting urea in the fall, which is not an efficient means of applying N. However, dual inhibitor stabilized fertilizer allows for that inefficient practice to become efficient by suppressing all three N loss mechanisms, as it contains both a urease and a nitrification inhibitor. This maintains a higher level of ammonium nitrogen for a longer period.

The choice of the right product, especially at the right rate, becomes essential in this practice, since some inhibitors, such as dicyandiamide, have a bacteriostatic rather than a bactericidal mode of action. In other words, they inhibit but don’t kill microorganisms. Further, dicyandiamide is 67 per cent N and serves a dual role as a controlled-release fertilizer. Research in Eastern Canada raised concern as it revealed that shallow banding (<two inches) results in greater losses than broadcasting of urea. Shallow banding is inadvertently carried out in many one-pass systems (side-banding or mid-row-banding). Research in Western Canada verified this observation.

In light of the above observations, it becomes apparent that enhanced efficiency fertilizers can simplify fertilizer application. For example, fall application of urea becomes more effective in Prairie environments. Further, single applications can replace split applications in humid environments. In the end, enhanced efficiency fertilizers, when used properly, can contribute to improved regional economic development and net farm income.

4R nutrient stewardship

The first step in managing your soil is knowing what’s in it. Therefore, soil testing is of high importance. We have already covered the basics of soil testing in a previous article. Then you need to decide what you are going to fertilize for — in other words, crop choice and potential yield. And finally, what you are going to fertilize with, which brings us to the choice of product.

The major factors that make a product’s effect different or the same include product chemical makeup, soil chemistry, plants and of course a combination of all of the above. The comparison of all the above factors will have to be based on the same placement, the same rate and the same time of application, which again brings us to the 4R principle.

Several different enhanced efficiency fertilizer products have been in existence for many years and a number have been recently introduced in the market. The enhanced efficiency fertilizer products can be divided into three major categories:

- Uncoated slowly available fertilizers containing N, such as urea-aldehyde, condensation products (e.g., urea-formaldehyde reaction products, sobutylidenediurea or IBDU), triazines, etc.

- Physical coating or barrier around soluble N fertilizer, such as sulphur-coated urea, polymer-coated/controlled-release urea, and combination products.

- Stabilized materials that include urease inhibitors, nitrification inhibitors, or dual inhibitors.

When it comes to major crops in Western Canada, only the first two categories are in use.

Let us examine these types of enhanced efficiency fertilizers starting with urease inhibitors.

When to consider urease inhibitors

The use of urease inhibitors is warranted and recommended when there’s a high risk of volatilization. Factors that will affect ammonia volatilization include:

- Soil moisture as it affects the dissolution of urea which is the first step in hydrolysis.

- High soil pH as it shifts pH equilibrium toward ammonia.

- Warm temperatures as the enzymatic rate is faster at higher temperatures.

- Low buffer capacity as soil is less able to resist localized pH increase.

- High crop residues as there is greater urease activity in plant residue, less soil contact and higher moisture content.

- And, finally, wind as it leads to evaporation and physical removal of ammonia.

In general, ammonia volatilization occurs due to a rapid rise in pH around an unprotected urea granule. When urea is applied to the soil, the enzyme urease mediates a reaction that causes it to hydrolyze. This reaction converts urea to ammonium (NH4+), which is great, as ammonium is a cation and can be adsorbed onto clay colloids.

The problem is that the reaction also creates bicarbonate that elevates the soil pH in the vicinity of the fertilizer granule. Increases of up to three to four pH units have been shown to occur in many studies. If the pH of the soil solution is less than 7.2-7.5, ammonium will be the dominant ion present. However, as the pH increases, ammonium is converted to ammonia and, of course, ammonia, being a gas, will result in loss.

Surface broadcast urea, spray-applied urea-ammonium nitrate or prolonged exposure of urea with no rain will worsen this loss. So will conditions such as heavy dew, followed by warm wind, especially under heavy plant residue.

As a result, many people use volatilization inhibitors for peace of mind or as insurance. But is this wise?

Recommendations to lower volatilization

Several practices have been recommended to reduce volatilization. They include:

- Use of urease inhibitors (Watson et al.1990), who demonstrated the benefit of using a urease inhibitor (NBPT).

- Slow-release forms (Rao, 1987), which demonstrated the benefits from the broadcast application of two slow-release sources, sulphur-coated urea and lac-coated urea.

- Irrigation shortly after application (Holcomb et al., 2011). The researchers plotted the amount of irrigation versus total ammonia N loss and demonstrated that when water is applied, there is an immediate reduction in ammonia volatilization with increasing irrigation rate. They found that irrigation with 30 mm (1.2″) of water resulted in approximately 0.5 per cent loss, whereas irrigation with two mm (0.08″) of water resulted in approximately 60 per cent loss.

All the above practices have been researched several times over the years. However, the most common practice in Western Canada has been deep banding the fertilizer into the soil, as in most cases the ammonia produced due to volatilization is absorbed by the soil above the deep band.

When it comes to deep banding, research in the ’70s with anhydrous ammonia showed higher yields than broadcasting other N sources, making people believe that it was a better N form. However, John Harapiak with Western Co-op Fertilizers (Westco) at that time suggested that urea should be placed in the same depth as anhydrous ammonia. In 1985 Harapiak published the average ratings from 28 trials carried out between 1977 and 1980, illustrating the benefits of deep banding. It turned out that it was banding, rather than the form, that was providing the advantage, since urea produced the same results.

In conclusion, deep banding remains the standard placement method of urea-based fertilizers in Western Canada. However, as the farm size increases, farm operators are seeking operational efficiencies and are switching to broadcasting. Research results in Western Canada support the use of urease inhibitors to minimize the risk of nitrogen losses when deep banding placement is replaced with either shallow banding or broadcast.

Volatilization stabilizers

North Dakota State University’s soil science department has extensively examined several volatilization inhibitors. In nine studies that were reported at the North Central Extension-Industry Soil Fertility Conference in 2011, several products demonstrated little value as fertilizer additives to inhibit urea hydrolysis, nitrification or ammonia loss from soil.

On the other hand, many studies have demonstrated the value of N-(n-butyl) thiophosphoric triamide (NBPT) as a volatilization inhibitor. For more information, I would strongly recommend that one should read the Nitrogen Extenders and Additives publication by NDSU.

Further research by North Dakota State University showed that NBPT-treated urea had the potential to increase grain yield and protein content of hard red spring wheat compared with a homogenous blend of urea and ammonium sulphate product, urea plus ammonium sulphate, and urea alone. Adding sulphur sources did not result in a yield advantage over urea alone. Urea treated with NBPT may optimize hard red spring wheat yields even at rates lower than the optimum fertilizer recommendation.

When to consider nitrification inhibitors

With nitrification and volatilization inhibitors, we are addressing three types of nitrogen losses: volatilization, denitrification and leaching. One important component to remember is that both nitrification and volatilization reactions are mediated by enzymes. Therefore, our aim is to minimize their action. Both leaching and denitrification losses occur due to nitrate.

The factors that affect nitrification are moisture (moist, not saturated), temperature (maximum approximately 27 C and minimum zero C) and pH (favoured by pH below seven and slowed by pH greater than six).

When we apply urea or ammonium fertilizers (e.g., ammonium sulphate), enzymes such as ammonia monooxygenase convert ammonium to nitrite (nitrification). These enzymes are found in soil bacteria and microorganisms. Nitrification inhibitors act to reduce the enzyme’s oxidation action and prolong the presence of ammonium in the soil. Limiting the nitrification of ammonium will also minimize the emissions of nitrous oxide.

A very interesting project was carried out back in the ’80s at the University of Saskatchewan examining leaching and denitrification losses of fall- versus spring-applied nitrogen. Up to approximately 35 per cent of autumn-applied 15N-labelled fertilizer N was lost via denitrification and seven to 20 per cent became immobilized by the following spring. Leaching was not responsible for the lower efficiency of fertilizer N. The potential denitrification rates were markedly higher in zero tillage and the population of denitrifying microorganisms was up to six times higher than in the conventional tillage fields. Further, crop residues doubled the gaseous N losses. Temperature above 5 C did not alter denitrification rates nor did a wide range of mineral N.

Are all nitrification inhibitors the same?

Again, the principle of the right source and rate has to be adhered to. Research at North Dakota State University showed that, for example, SuperU and Instinct maintain urea in the form of urea and/or NH4+ for an extended period whereas other products behaved as non-treated urea. The reason for this benefit is based on the fact that these products protect nitrogen from loss, since nitrogen in the ammonium form is not at risk of leaching and denitrification losses.

Check the active ingredient concentration

The concentration of the active ingredient delivered by a product has a direct effect on how well a product will inhibit loss of nitrogen through nitrification as well as ammonia volatilization. For example, research dated back to the ’60s demonstrated that higher concentrations of dicyandiamide (DCD) equate to a higher percentage of nitrification inhibition. Furthermore, a concentration of approximately one per cent of the active ingredient is required to obtain maximum protection from denitrification.

However, it is impossible to coat urea, for example, with that level of DCD. Hence the inhibitor is added to the product when it is in the liquid form, (i.e., before granulation). I reported on some research back in 2019 with three products — one containing 8,500 ppm of DCD and 600 ppm of NBPT, the second 870 ppm DCD and 600 ppm of NBPT and the third 665 NBPT. I demonstrated that the second and third products performed equally in inhibiting volatilization. However, the second did not perform equally with the first in inhibiting denitrification as a result of the lower concentration of DCD.

Dual inhibitors

Dual inhibitors provide both a urease inhibitor and a nitrification inhibitor with one coating. The advantage of using dual inhibitors lies in the fact that the urease inhibitor will prevent volatilization. Meanwhile, the nitrification inhibitor will prevent leaching and denitrification — in other words, integrated active ingredients.

This results in both immediate and extended N availability, while extending the safety to soil biology. The only possible disadvantage would be that dual inhibitors do not offer time delay or a controlled-release mechanism. Fertilizer placement will affect the effectiveness of the dual inhibitors. Deep banding of urea treated with dual inhibitors has shown no benefit over untreated urea in many studies whereas when broadcasting or shallow banding they showed tremendous benefits.

Polymer-coated/controlled-release ureas

Now we turn to enhanced efficiency fertilizers with a physical coating or barrier around the soluble N. The products in this category that are used in Western Canada are known as polymer-coated urea or controlled-release urea. It is important to understand nitrogen demand for various crops and nutrient application timing to make proper use of these products.

Polymer-coated urea can improve plant uptake of the nutrient when properly applied — in terms of timing and placement — and reduce losses of nitrogen to the environment. Also, depending on climate conditions, it can alter nutrient availability timing so nutrient is available when crops need it.

Adherence to the 4R nutrient stewardship principle is of utmost importance, as some components differ from other enhanced efficiency fertilizers. Right time is still important with polymer-coated or controlled-release urea. In order to be successful in using a polymer-coated product, one must understand when peak N demand is for their crop. For example, if the “delayed-release fertilizer” delays the nitrogen availability past when the crop needs the N the most, the producer will suffer yield loss.

It is extremely important to remember that moisture is needed for polymer-coated ureas to work. This is because the polymer coating protects the urea. The polymer coating helps prevent volatilization losses, but moisture needs to enter the granule and dissolve the urea so the urea can diffuse through the coating. The nitrogen then moves into the soil.

However, if there is no moisture, urea can be stranded inside the coating. If one broadcasts the polymer-coated urea instead of placing it in the soil, especially in drier environments, the lack of moisture means fertilizer granules sit on the soil surface. While stranded on the surface, they won’t become hydrated. Therefore, broadcasting polymer-coated urea without incorporating it in Western Canada is not usually advisable because lack of moisture means fertilizer granules sit on the soil surface and volatilize.

The photo in Figure 1 was taken seven weeks after the broadcast application of polymer-coated urea. One can observe here that the broadcast polymer-coated urea was stranded by lack of moisture, which can occur in prairie environments. This can lead to increased volatilization which means your crop won’t get to use it, which is like letting your profits evaporate. Therefore, incorporating polymer-coated urea will decrease volatilization and increase plant uptake.

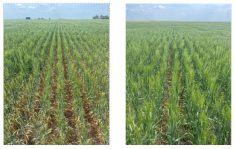

Back in my Westco days, we carried out 18 experiments to determine the suitable conditions for controlled-release urea application in Western Canada. Figure 2 was taken during a three-year experiment with forages in the Peace River region and illustrates why controlled-release urea should be incorporated into the soil. Delay in release of N from controlled-release urea meant the crop was unable to take advantage of the N during the best growing conditions.

Polymer-coated ureas and seed placement

Seed-placed polymer-coated urea provides an effective means of reducing seedling injury from seed-placed nitrogen. From a 4R point of view, this consistently provides the best placement for polymer-coated urea products. Research in Western Canada has shown that polymer coating dissolves to sync well with canola’s maximum N uptake. And although wheat and barley demand is less well-timed to polymer coating dissolution, it still constitutes an effective method of placing polymer-coated ureas, especially since when untreated urea is seed placed, it is where the plant needs it, but can burn the seedling. Polymer-coated urea is recommended with winter wheat only when all N is intended to be placed with the seed and rates of N are more than 55 lb. N/acre. Based on the time of application and placement, the economic response of polymer-coated urea use is as follows: fall-banded polymer-coated urea < spring-banded polymer-coated urea < seed-placed polymer-coated urea < seed-placed polymer-coated urea/urea blend. The greatest opportunity for economic benefits with polymer-coated urea was for canola followed by wheat and barley.

Both soil temperature and soil moisture govern polymer-coated urea N release. Cool conditions at seeding will slow the release of N from polymer-coated urea. Lack of contact with soil moisture may also affect the release rate; therefore, polymer-coated urea should be applied such that it has soil contact. It is recommended that a blend of polymer-coated urea and readily available N (e.g., urea or ammonium sulphate), be used to supply immediate early-season crop N needs, and polymer-coated urea-N for season-long feeding of a crop. The economic benefit of a 25 per cent urea-75 per cent polymer-coated urea blend was shown by Alberta Agriculture.

Polymer-coated urea is a technology that “works,” i.e., provides protection of urea under conditions of high volatilization. High volatilization conditions are not predominant in many parts of Western Canada unless the 4R principle is not adhered to. Simply replacing your standard urea usage with polymer-coated urea can result in poor economics, especially in drier environments. It is important to understand where in your cropping system polymer-coated urea can bring value.

Right place and time

To summarize, there are many instances when nitrification inhibitors can be effective in Western Canada. These include:

- any conditions that will lead to losses from nitrates due to denitrification.

- fall application or early spring applications.

- slow spring melts.

- irrigation.

- wet, light soils, or wet, heavy textured soils, or continually wet soils.

Further, one has to consider the conditions, such as seasons and soil types, under which nitrogen losses will be minimal. Those include seasons and soil types where nitrogen-loss conditions occur after the nitrification inhibitor has become ineffective or when soil-plus-fertilizer nitrogen far exceeds crop nitrogen requirement, whether this is intentional or a result of weather conditions.

Also, for the inhibitors to be effective, they have to be in proximity with the NH4 in the soil. Therefore, any separation between a nitrification inhibitor and NH4 — or where the positional availability of NH4 is a factor especially under dry soil conditions — could reduce any benefit from an inhibitor. We should also keep in mind that there is no single “best” fertilization system since every farm, field and year has unique demands, resources and conditions.

Conclusions

Several take-away messages can be derived from this article:

- Know your fertilizer placement depth. If it’s not deep enough, stabilize.

- Efficiency is about potential loss versus the value of time. Understand how valuable time can be, since completing operations in a timely manner can contribute to increased profitability.

- Rate matters. Know the science behind the products you are using and recommending. Ask questions. Make sure there are third-party data. Again, remember the definition of enhanced efficiency products. They allow increased plant uptake, therefore, should be used at lower rates than non-stabilized products.

- Find the balance between agronomics and economics. The highest possible yield does not usually mean the most profitable crop. Nitrogen management tools can help you and your client determine the maximum economic yield.

- Focus on the fundamentals of crop nutrition first. Know when the crop needs nitrogen, then apply it when the crop can use it.

- If the conditions do not warrant the use of inhibitors, your client doesn’t need them.

To take the CEU quiz for this article, CLICK HERE.

References

Karamanos, R.E. and Henry, J.L. 2007. A Water-Based System for Deriving Nitrogen Recommendations in the Canadian Prairies. Chapter 11, in.

Bruuslema, T. (ed.). Managing Crop Nitrogen for Weather. Proceedings of the Symposium “Integrating Water Variability into Nitrogen Recommendations.” International Plant Nutrient Institute, Norcross, Georgia.

J. Environ. Qual. 38:1383–1390 (2009) and 42:1635–1642 (2013).

Watson et al. 1990. Effectiveness of the urease inhibitor NBPT (N-(n-butyl) thiophosphoric triamide) for improving the efficiency of urea for ryegrass production. Fert. Res. 24:11-15.

Rao, D.L.N. 1987. Slow-release urea fertilizers — effect on floodwater chemistry, ammonia volatilization and rice growth in an alkali soil. Fert. Res. 13:209-221.

Holcomb, J.C. et al. 2011. Effect of irrigation rate on ammonia volatilization. Soil Sci. Soc. Am. J. 75:2341-47.

Thapa, R., Chatterjee, A., and Cattanach, N.R. 2015. Managing nitrogen loss for hard red spring wheat, Crops & Soils: Volume 48, Issue 5, p. 22-24.

Aulakh, M.S and Rennie, D.A. 1986. Soil and Tillage Research 7:157-171

Goos, J.R. and Guertal, E. 2019, Evaluation of Commercial Additives Used with Granular Urea for Nitrogen Conservation. Agronomy Journal 111:1-7.

Karamanos, R. 2019, The Impact of DCD and NBPT Concentration on Nitrification and Volatilization, Soils and Crops 2019, 5 March, Saskatoon.

Tiessen K.H.D., Flaten D.N., Grant C.A., Karamanos R.E. and Entz M.H. 2005. Efficiency of fall-banded urea for spring wheat production in Manitoba: Influence of application date, landscape position and fertilizer additives. Canadian Journal of Soil Science 85:649-66.

Tiessen, K.H.D., Flaten, D.N., Bullock, P.R., Burton, D.L., Grant, C.A. and Karamanos, R.E. 2006. Transformation of Fall-Banded Urea: Application Date, Landscape Position, and Fertilizer Additive Effects. Agronomy Journal 98:1460-70.

Karamanos, R.E. 2017. Fall and Spring Placement of Nitrogen Fertilizers. Where do Enhanced Efficiency Fertilizers Fit. in Proceedings 2017 Manitoba Agronomist Conference, December 13-14, Winnipeg, Faculty of Agricultural and Food Sciences, University of Manitoba, Winnipeg, Manitoba.

Karamanos, R. 2013. Nutrient Uptake and Metabolism in Crops. Understanding the Basics of Crop Growth and Development, Prairie Soils and Crops 6:52-63.

Kryzanowski, L., Akbar, A., McKenzie, R.H., Middleton, A.B., Sprout, C., Henriquez, B. and O’Donovan, J. 2010. Enabling Adoption of Environmentally Smart Nitrogen (ESN) Technology to Maximize Economic Returns and Environmental Benefits in Alberta. Alberta Agriculture and Rural Development and Agriculture and Agri-Food Canada. Edmonton, Alberta 103 pp.