Gord Ellis and Wade McAllister are two Alberta producers who say properly designed, field-scale, on-farm research projects over the past couple of growing seasons have provided some valuable information relevant to their farms.

Both producers were involved in the relatively new Plot2Farm program developed by the Alberta Wheat and Barley Commissions.

In 2020, Ellis, of Ellis Agriculture Ltd. at Olds, Alta., did a yield comparison between AC Foremost, a former CPS wheat that is now classed as Canada Northern Hard Red (CNHR), and AAC Goodwin, a newer CPS variety. And then, in 2021, he evaluated the effect of Moddus plant growth regulator on malt barley.

Read Also

AgraCity’s farmer customers still seek compensation

Prairie farmers owed product by AgraCity are now sharing their experiences with the crop input provider as they await some sort of resolution to the company’s woes.

At McAllister’s Antler Valley Farm near Innisfail, the field-scale research project in 2021 evaluated the difference between seeding wheat on 15-inch row spacing versus 7.5-inch row spacing.

Results on these on-farm research projects (details to follow) were relevant and useful to these two farms, but what really made the information valuable is the way the field studies were organized.

They weren’t just simply side-by-side, treated versus untreated comparison strips seeded in the spring and harvested in the fall. As part of the Plot2Farm program, they were much more structured trials than that, says Jeremy Boychyn, agronomy research extension specialist with the Wheat and Barley Commissions and co-ordinator of the Plot2Farm program.

The idea is to conduct these studies on a field-scale basis but under proper research protocols, says Boychyn. That means they are properly laid out, each research treatment is replicated four times on the farm, a uniform piece of ground is selected to conduct the study, but the field-scale plots are randomized over that field. The project is monitored throughout the growing season, and at harvest the yield from each plot is collected and properly weighed in a weigh wagon. The program also provides funding to cover the cost of a professional agronomist to work with each farm to set up and monitor the project during the year of the research trial.

Applications open ’til February

The Plot2Farm program got off the ground in 2020, and last year involved eight producers who implemented on-farm research trials on their farms. The program is looking to involve more producers in the 2022 growing season.

“We have been easing into the Plot2Farm program and this coming season we are hoping to expand it further,” says Boychyn. Based partly on input from commission directors, Plot2Farm has about a dozen protocols (project ideas) of its own involving both wheat and barley crops. And Boychyn says producers who are members of the Alberta Wheat and Barley Commissions are welcome to suggest other research ideas as well.

“For the 2022 growing season, any producers interested in being involved in on-farm research can apply through the program website at Plot2Farm.com,” says Boychyn. Farmers can select one of the protocols listed or suggest something more specific to their farming operations for consideration. The deadline is Feb. 1, 2022, for applications for the coming growing season.

Boychyn says while there is no specific number in mind, there is a limit to how many producers the program budget can accommodate for 2022, but producer members from across the province are urged to apply.

Some of the existing research ideas or Plot2Farm protocols for wheat in 2022 include variety trials, evaluation of Manipulator plant growth regulator and assessment of enhanced efficiency fertilizers. Some of the barley protocols include looking at increasing nitrogen fertilizer rates for malt and feed varieties, malt and feed barley variety comparisons and fungicide timing, to name a few.

Producers are urged to apply, and a number of projects will be selected. Then, the Plot2Farm program will provide farmers with step-by-step guides on how to implement the trials on their farms. And professional agronomy services will also be available for all successful projects.

What the research showed

Back to what farmers Ellis and McAllister learned from their on-farm research trials.

On his farm near Olds, Ellis was looking to find a different CPS wheat variety to replace AC Foremost. He had grown the high-yielding AC Foremost for years when it was originally classed as a CPS variety, but in a reclassification program in 2015, the Canadian Grain Commission moved AC Foremost into the new CNHR class and into a different (lower value) market.

Ellis figured for this first Plot2Farm project he would set up a research trial to compare AC Foremost with AAC Goodwin, a CPS wheat developed at the Agriculture and Agri-Food Canada research centre at Swift Current. Could AAC Goodwin be an economic replacement for AC Foremost?

Working with the guidelines provided by Plot2Farm and with assistance from Jeremy Boychyn, a uniform field was selected for the trial, plots were laid out and flagged. The plan called for four plots of AC Foremost and four plots of AAC Goodwin, randomly placed over the field.

“Once we got it laid out, basically the plots were a drill-width wide and the length of the field, which was about a half-mile long,” says Ellis.

The trial was seeded using a 50-foot Bourgault 3320 Paralink with three-inch paired openers, 10-inch row spacings and mid-row banders. The target plant stand was 30 plants per square foot. Seeding rates were determined using thousand kernel weight, germination percentage and mortality percentage. Seeding rates were 146.4 pounds per acre and 169.5 pounds per acre for AC Foremost and AAC Goodwin, respectively. Three weeks after seeding, the actual plant count for each variety came in very close to the target of 30 plants per square foot. AC Foremost plots had 29 plants per square foot while AAC Goodwin came in at 28 plants per square foot.

At harvest, data was collected from a single combine pass within each research plot. Yield measurements were taken using a weigh wagon. “We took a full header width down the centre of each research plot and weighed that grain,” says Ellis.

Bottom line from this research project — the AC Foremost outyielded AAC Goodwin by 23 bushels per acre (123 bushels per acre for AC Foremost versus 100 bushels per acre for AAC Goodwin). For Ellis, those results were a no-brainer. AAC Goodwin is no doubt a good CPS wheat variety but yield-wise it was not a replacement for AC Foremost.

In the second Plot2Farm project in 2021, Ellis looked at the effect of Moddus plant growth regulator (PGR) on malt barley. “Lodging can be an issue on our farm, so we are interested in a treatment that allows us to maintain fertility to optimize yield and yet reduce the risk of lodging,” says Ellis. Moddus is a relatively new PGR developed by Syngenta, ideally suited for barley, and a product accepted by malting companies for use on malting barley.

Ellis says for this on-farm research trial he seeded a uniform field to AAC Synergy malt barley, and within that field four plots to be treated with Moddus PGR were marked out, while leaving another four plots untreated. Again, the location of the plots was randomized.

The fertility package for the whole field included 87.5 pounds of actual nitrogen, 33 pounds of P2O5 phosphorus and 39.1 pounds of potassium per acre. Again, the crop was seeded with a 50-foot Bourgault 3320 Paralink drill with three-inch paired openers on 10-inch row spacing.

Boychyn helped with the plot layout and seeding. He also monitored crop staging with the PGR applied to the designated “treated” plots at the optimal plant growth stage 31.

Ellis says while he learned something about the PGR, 2021 probably wasn’t the ideal year to test Moddus because of the dry growing conditions. “None of the malt barley lodged this year because it was so dry,” he says. His area saw about five to six inches of moisture during the growing season, which is about half of normal.

All of the malt barley stood well for the entire growing season; however, at harvest, the Moddus-treated plots did produce a 5.1 per cent yield increase (about four bushels per acre) over the untreated or check plots of barley. The Moddus plots had an average yield of 88.2 bushels per acre, while the untreated plots averaged 83.9 bushels per acre.

While the Moddus-treated plots had higher yield, the quality was a bit off, with fewer plump kernels, more thins, and more peeled and broken kernels. The quality factors were statistically significant, however, not serious enough to affect malt acceptance.

What about row spacing?

The big question for McAllister and his brother, Scott, at Antler Valley Farm was whether they could seed a profitable wheat crop on a wide 15-inch row spacing. Their rotation most years is primarily canola, wheat and barley, although they sometimes grow hybrid fall rye and are just starting to include peas.

The brothers were among some of the first in Western Canada to buy a new 60-foot SeedMaster Ultra SR drill. This is a single rank implement, which is much simpler to use, and with lower capital costs and lower horsepower requirements; however, on their fifth-generation farm, the question was can they seed a profitable wheat crop on 15-inch row spacing?

The concern with wider spacing, according to McAllister, involved getting the wheat crop dense enough to reduce or prevent tillering and ideally produce more seed on the main stem.

“We really didn’t have any concerns about the canola because on the wider row spacing, plants just branch out and produce more pods on more branches,” says McAllister.

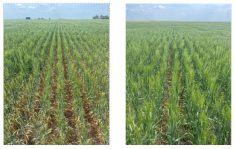

The idea with the Plot2 Farm project was to compare wheat on 15-inch row spacing with wheat seeded on 7.5-inch row spacing. McAllister says since it is hard, if not impossible, to find a drill with 7.5-inch row spacing, they opted to seed their whole on-farm research field first with the new drill at 15-inch spacing and then come back using RTK guidance and make a second pass on four plots seeding between the rows, to create those plots with crop seeded on 7.5-inch row spacing.

They applied the same fertility to the whole research area, which included 198 pounds of 46-0-0 as well as 129 pounds of 11-52-0 per acre. Seeding AAC Penhold CPS wheat, the brothers targeted a seeding rate that would produce 38 plants per square foot on both spacings.

A plant count 21 days after seeding showed about 33 plants on the 7.5-inch row spacing and 38 plants on the 15-inch spacing.

The plots were monitored for the growing season and then the yield from a combine width the length of each plot was weighed. The final figure? The wheat crop grown on 15-inch row spacing yielded three bushels less per acre than wheat grown on the 7.5-inch spacing. That was a win as far as McAllister was concerned.

“Going into this research, I figured the wider spacing might produce a lower yield, but I was prepared to see a five-bushel yield difference,” he says. “Three bushels was better than I expected.” He doesn’t anticipate any yield loss using the same drill to seed both canola and barley.

McAllister says the benefits of being able to use this drill and wider seed row spacing for all crops on the farm far outweighs the value of three bushels of wheat.

“We’re not going to lose the farm over those three bushels,” he says with a laugh. “Often when we think about crop production it is all about yield, yield, yield. And it is important, but there are other factors to consider too. For us, the operational cost savings of using this drill are considerable. If we can spend less on equipment and perhaps only be short about three bushels of yield, we are definitely ahead of the game.”

More details on the economics of using a single rank, wide-row spacing drill on the McAllister farm will be featured in a February issue of Grainews.

Both Ellis and McAllister say the extra time and management needed to set up the Plot2Farm on-farm research trials are well worth the effort.

“It is just an excellent approach to on-farm research providing information we can trust,” says McAllister. “It allowed us to collect data specific to our farm. We tested how row spacing impacts wheat yield and quality. The trial results have helped us gain further understanding of our farm management and equipment changes.”

Ellis agrees. “The way the protocols are set up, it really adds value to the data that is collected,” he says. “The research plots are replicated and they are randomized, so the results are information you can trust. Plot2Farm takes on-farm research to a whole new level, making it possible to do research with our own equipment under our own growing conditions.”