If you’re reluctant to measure the seed your combine is leaking and adjust the machine accordingly, you may be leaving a lot of yield in the field. That was Jim Bessel’s message to farmers during EvolveAg’s field day in north-western Saskatchewan in July.

Bessel, who worked with the Canola Council of Canada for over 20 years before retiring into a consulting position, cited research from a three-year study looking at canola harvest losses. Harvest losses ranged from 2.3 per cent to over 11 per cent. The study, led by Rob Gulden of the University of Manitoba looked at 310 western Canadian fields and wrapped in 2012.

Read Also

AgraCity’s farmer customers still seek compensation

Prairie farmers owed product by AgraCity are now sharing their experiences with the crop input provider as they await some sort of resolution to the company’s woes.

Combines don’t leave the lot set for each farm, Bessel told farmers.

“The point is they’re done with an algorithm and a computer that’s certainly not related to your conditions in your field and you as an operator,” Bessel said. That means farmers are better off doing a little testing on their own, he said.

So how can you curb harvest losses and the next year’s volunteers? The key is to do a little testing in your own fields, Bessel said. Here’s a four-step guide to finding and plugging those leaks.

1. Catch a sample

When it comes to capturing that sample, you have plenty of options. You can buy a magnetic tray to attach to your combine, or Red-Green something yourself.

“Anything’s better than that darn No. 9 scoop shovel,” said Bessel.

Whichever tray you choose, you’ll need to switch off the chopper and spreader to get a representative sample, Bessel said. The formulas for calculating grain loss use trays that are a square foot.

One option is to set a tray in the crop and drive over it, Bessel said. Another do-it-yourself option is to attach a handle to a tray. Bessel prefers a paint extension pole, which allows him to telescope the tray several feet from where he is.

If using a tray on a pole, Bessel has someone drive him alongside the combine, while he sits in the back of the truck or quad. He holds the tray, face-down, behind the combine. Once the combine reaches its normal harvest speed and is pulling in a normal amount of grain, the combine operator flashes a thumbs up. Bessel flips over the tray and the truck or quad stops.

“Let the combine pass over… the full one square foot,” said Bessel.

Bessel recommends making sure the handle is fully extended so you’re a reasonably safe distance from the combine. Regardless, you’re going to get dirty, he said, and if you don’t like getting dirty, “tough bananas.”

“It’s very expensive when you don’t want to get dirty. The shower is pretty cheap.”

Farmers can also buy magnetic trays. Bessel had one that could be moved to different machines. It could be set behind the axle, or near the table, to capture wayward grain. It also had a remote control. Push the button and the tray drops, he said.

2. Measure the loss

To figure out how much grain you’re leaving behind, you’ll need two numbers: the weight or volume of the clean sample and your combine’s concentration factor.

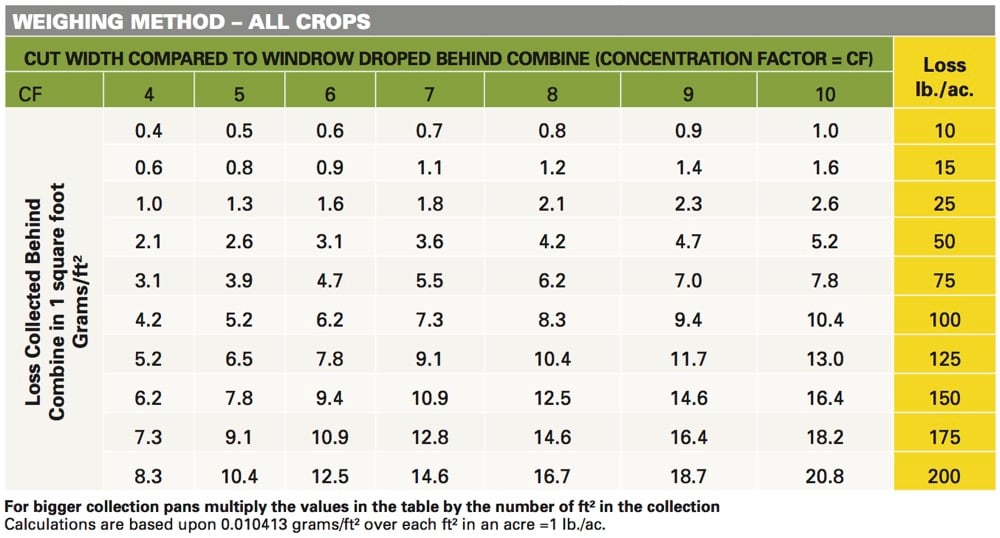

The Canola Council of Canada and the Prairie Agricultural Machinery Institute (PAMI) have a handy table (below) to figure out your combine’s concentration factor. The concentration factor is determined by the width of the combine’s cut and the width of the discharge out the back. Most combines are five or six feet wide at the back, but use your measuring tape, said Bessel.

Before measuring the sample, you’ll need to clean it. You can use a screen to remove straw and chaff, according to the Canola Council. Or you can put the sample into a five-gallon pail and blow out the chaff with a hair dryer or blower.

Armed with those two numbers, you then need to consult the charts published by the Canola Council and PAMI. Those charts will spell out your losses in bushels per acre (if you measured volume) or pounds per acre (if you went with grams).

3. Adjust the machine, or driving style

Now it’s time to fix any problems. Bessel recommended starting at the front end and working your way backwards. The Canola Council also suggests searching for leaks at the front first — specifically the pickup, feederhouse, elevator, shoe seals, grain tank and separator covers.

If you adjust your settings, only change one thing at a time, Bessel said. And recheck losses between adjustments, the Canola Council recommends.

When it comes to combines, there’s a big difference between a driver and an operator, Bessel said. He suggested spending the dough to train someone, and offering an incentive to operators who save bushels.

Who makes a good combine operator? Someone who listens, asks questions and doesn’t push the throttle, Bessel said.

4. A quick, dirty method

As the days fade into evenings, environmental conditions change. And that affects your harvest losses. “Thrashing changes. Moisture content, all of that starts to change,” said Bessel.

But that doesn’t mean you have to redo the test in full. Instead, Bessel suggested giving the “Frisbee special” a throw.

Bessel’s Frisbee is a square-foot lid that can be tossed under the combine to catch a sample. “And most often once you get onto it, you can get pretty good. The big thing is to stay safe and not get run over by the tires.”

Once you’ve cleaned the sample, you can use felt pen markings in the corners of the Frisbee to measure the sample. For example, canola that fills a three-inch area in the corner represents about a one bushel per acre loss (assuming a combine concentration factor of five or six). Canola seeds need to be rolled and flattened into the corner, Bessel said.

It’s a “quick and dirty” method that gives you something to work with, Bessel said.

“You can do this even with a flashlight at midnight if you really want to get on somebody’s case about how fast they’re driving.”

For more tips on reducing harvest losses with canola, visit canolawatch.org.