seed tender_CR2

Having a seed tender gives the farm a huge boost in efficiency during seeding time. A third drive axle was added to handle the weight.

Photo: Travis Warkentin

ST Conveyor

Positioning the air seeder’s conveyor is no longer necessary when there is a hydraulically controlled conveyor mounted on the back of the seed tender.

Photo: Travis Warkentin

ST new drive

The new drive axle was placed in front of the existing two. The gears in the new differential had to be changed to match up with the gears in the old ones.

Photo: Travis Warkentin

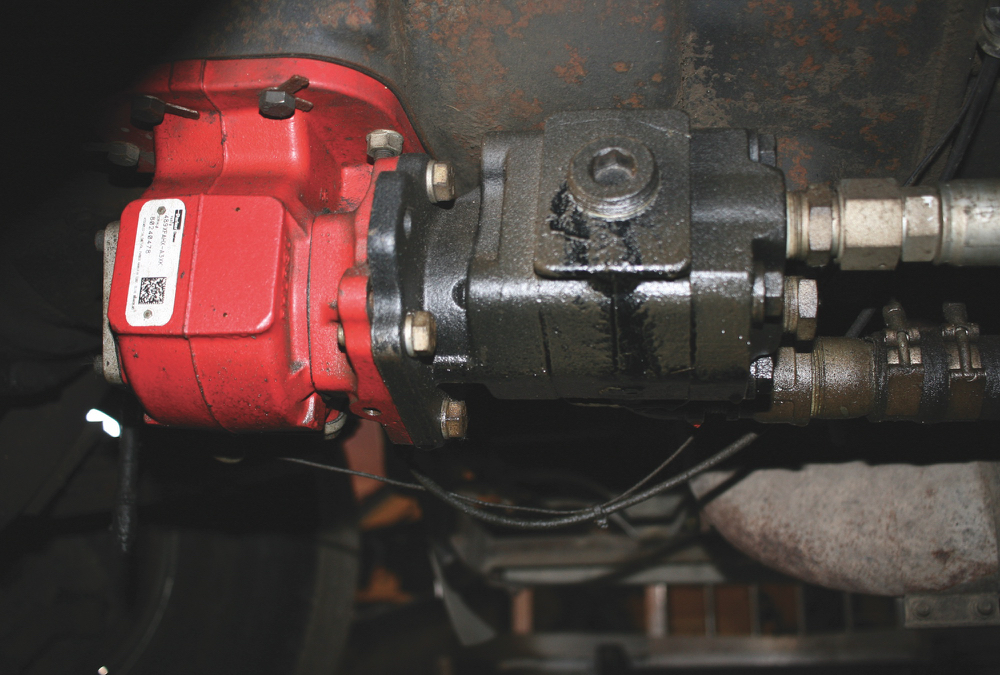

ST PTO

A new, more reliable, transmission- mounted PTO pump was installed after the old pump failed.

Photo: Travis Warkentin

ST regulator

The airline regulator controls the air pressure on the new front drive axle. Pressure is manually added when the load is increased.

Photo: Travis Warkentin

By far the biggest efficiency booster on my farm has been the addition of a seed tender, which has substantially cut down our air seeder and planter-fill time. Additionally, it has reduced the number of vehicles needed at the field. We used to take one tandem axle truck and two single axle trucks to service the air seeder. Now we only need to take one.