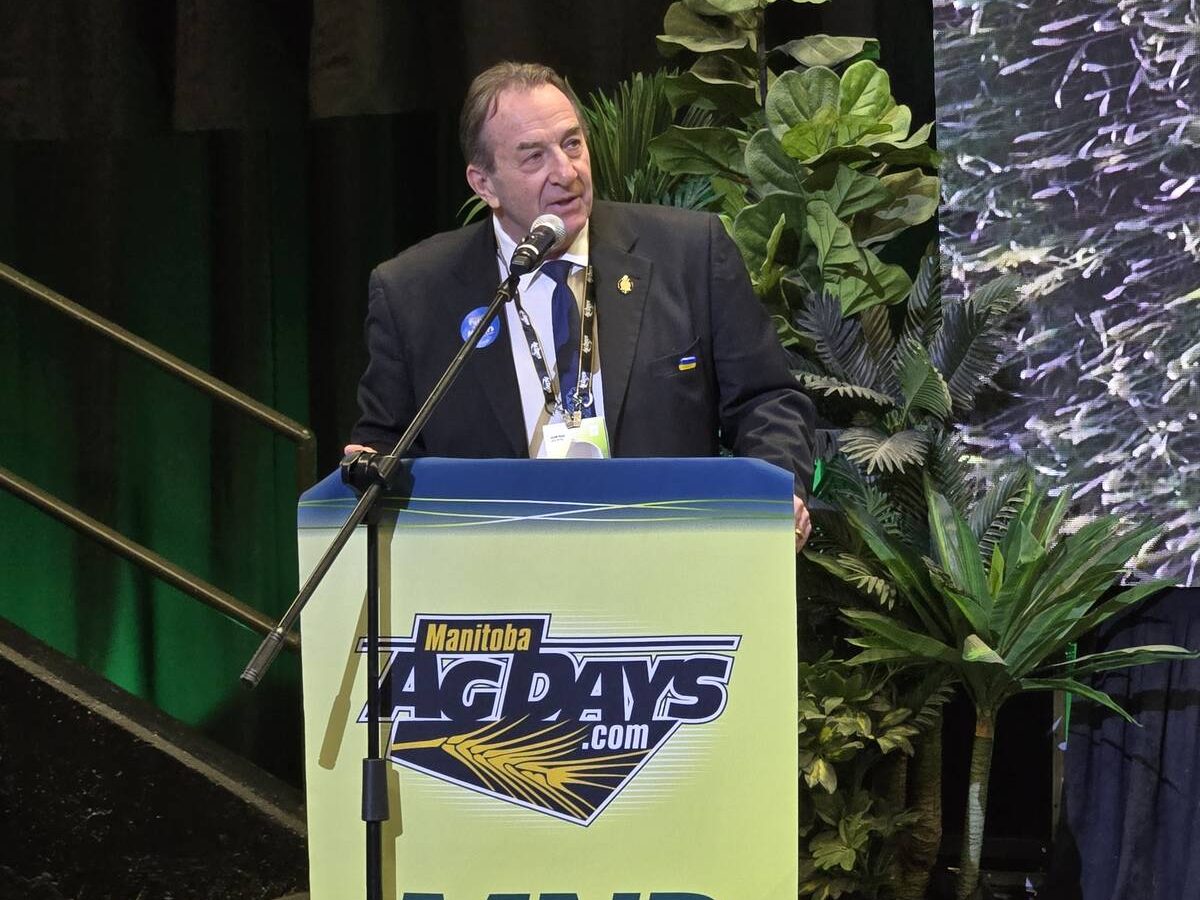

It’s a question Marc Beland has been asked more times than he can remember: what are biologicals?

“That’s a very good question. I get that quite often,” Beland says with a laugh.

Read Also

Manitoba crop insurance expands wildlife coverage, offers pilot programs

New crop insurance coverage is available to Manitoba farmers.

Beland is the director of market development for Premier Tech, which offers a variety of biological inputs to the agriculture market.

He may hear that same question even more often in days to come. A recent survey of nearly 800 farmers from across the country, conducted by Corteva Agriscience, showed growing interest in biologicals. Seventy-nine per cent of respondents said they are already using or are interested in learning more about biological and biostimulant products. Eighty-two per cent said they would consider adding a biostimulant to their crop nutrient plan.

By definition, biologicals are inputs or products created from naturally occurring micro-organisms, plant extracts, beneficial insects or other organic compounds. Think of a naturally occurring organism or substance that enhances, but doesn’t replace, natural processes to stimulate an increase in nutrient uptake or use efficiency in crops. Biologicals also allow growers to reduce the use of some chemical and fertilizer inputs.

They can be grouped into one of three categories: biostimulants, biofertilizers and biocontrols.

Biostimulants are perhaps the most commonly known of the three and can include microbials that produce or alter plant hormones to stimulate growth, nutrient uptake or relieve abiotic stress. They can also include amino acids or protein hydrolysates that provide available nitrogen and stimulate microbial activity. Other examples are seaweed and plant extracts with an antioxidant effect that can relieve stress and promote microbial activity.

Driving interest

Dale Cowan is strategy manager and senior agronomist for AGRIS Co-operative, a full-service, farmer- owned co-op with 10 retail locations in Ontario. AGRIS offers a number of biological products and Cowan says interest in them has spiked as the number of products and research into those products has climbed.

Cowan says much of this interest resulted from recent research that indicates as much as 70 per cent of yield can be determined by abiotic stresses including hot or dry conditions.

“That’s what’s driven this industry. If you know drought is coming, do we have a product that increases water-use efficiency in the plant and can help us get ahead of that drought?

“What product do I use and do I put it on before or after or during? And what’s my yield response going to be? That’s the big question mark and that’s where everyone struggles, is to figure out what’s the most efficacious way to use these products. Filling this gap between planting and harvesting, is there something I can do in between times of the critical growth stage just to keep adding yield potential?”

Although biologicals such as biostimulants can address some stresses, Cowan cautions that they are not a cure-all.

“These things are designed to alleviate abiotic stresses or lessen the effect of biotic stresses,” he says.

“The yield gains here are rather nominal on these products. They’re not a panacea for fixing production problems. They are designed to alleviate some of these stresses at critical times through the growing season.

“They’re not going to replace good management decisions and good base fertility and good agronomic practices. They’re designed to augment and supplement (them).”

Importance of education

Beland says it’s important for companies like his to educate growers and agronomists on how these products work.

“That’s one of the important pillars we have at Premier Tech and that’s education. If you don’t help and educate the end user, he doesn’t really know what the benefits are or what to look for.”

“Having that education portion of things … is important, to be able to read different labels, to see which are viable and which are not, which are more crop specific and which are more general. We need to educate and have farmers understand and be able to process things so they make sense and they can decide if they want to use this tool on their farm.”

What’s the problem?

Cowan says one of the first things agronomists should discuss with clients about biologicals is the kind of problem or issue they want the products to address.

“Selling a product just for the sake of selling a product without knowing where it fits or whether it’s going to do any good, that’s a moderate risk to a high risk situation,” he says.

“We have to have a purpose for recommending some products. What we don’t want to do is recommend them and say ‘you’ll be amazed.’ Amazed at what? We have to try to be very specific.”

Cowan also urges caution when using a biological product for the first time. He says agronomists may want to recommend that their clients conduct on-farm strip trials with any new biologicals.

“The only real way to definitively understand the thing you’re doing on your farm under your system or our agronomy practice is to do strip trials,” he says.

“All of a sudden we’ve got 25 replications, 50 replications across the field that you can pick up with your monitor. You’ll soon know whether these things are adding to yield or helping the bottom line.”

Cowan, who was inducted into the Ontario Agri- cultural Hall of Fame earlier this year, says agronomists should make their clients aware that many of the companies that produce biologicals are eager to work with farmers. In some cases, they are willing to give product to a producer in exchange for results from crop trials.

“Probably the biggest advantage I’ve seen to some of these mainline companies buying these smaller biological companies up is they are investing in research,” he says.

“There’s actually been some major investments going into the research, which wasn’t always the case with some of these biostimulants in the past. They tended to be promoted based on someone’s experience or testimonial type advertising. As agronomists dealing with farmers (making) serious investments, we’d rather have the data.”

What works, what doesn’t

Jarrett Chambers is the founder of ATP Nutrition, a Canadian-owned and operated nutrient company. When selecting biologicals, he says farmers and agronomists should learn not only where it will work, but also where it won’t.

“It’s not Frank’s RedHot sauce. You don’t put this stuff on everything,” he says.

Chambers also recommends that agronomists emphasize to their clients that biologicals should only be used as part of a well thought-out fertility program.

“You can’t use it in isolation. Be sure you already have a good fertility program and let’s make it more efficient,” he says. “Have that conversation in the months of October through April and then go to your farm and say where do I think there’s areas for improvement and see if that biological or biostimulant can fit into that.”

Cowan says it’s also important for producers and agronomists to know the kinds of products that biologicals can be mixed with. For example, some products are not compatible with urea ammonium nitrate or herbicides.

Also of note is that most biostimulants and other biological products have a limited shelf life. Care must be taken so they don’t go to waste.

“They’re not like other inert chemicals. They’re living entities,” he says.

To that end, agronomists should read product labels and advise clients on proper storage, including any temperature restrictions.

“Get an understanding with your grower that we’re going to use this product at such and such time,” Cowan says.

“It’s this whole idea of building a relation- ship with your customer so we both have an understanding of what it is we’re doing here and that I’m not going to have stuff in inventory and an endless product supply in case you might want to try it. It really changes the supply chain dynamics with these products.

Pre-crop planning

Beland agrees that getting as much information as possible on biologicals and how they work is an integral part of any pre-crop planning. That should include detailed information on how a product performed in trials and whether an independent third party compiled the results.

In the case of Premier Tech, the company works with a number of third party collaborators to verify the efficacy of its product in terms of yield gains and to benchmark them against other biologicals on the market.

“Obviously, there’s an educational portion where we need to explain how (the product) works. But at the end of the day, it’s also about what ends up in my pocket as a farmer. Sure, we can show the quality and the performance, but it’s what ends up in the bin and what they invested and how much more they’ve got (that’s important).

– This article was originally published in the November 2023 issue of GrowPro magazine.